Introduction:

Battery spot welding machines are essential tools in the production and assembly of battery packs, particularly in the electric vehicle and renewable energy sectors. Understanding their working principle and proper usage can significantly enhance the efficiency and quality of battery assembly.

Battery Spot Welding Machine Working Principle

Battery spot welding is a process that joins two or more metal surfaces together by applying heat and pressure. This is achieved through the use of an electric current that flows between the workpieces. The basic components of a spot welding machine include:

1. Electrodes: These are typically made of copper and are used to conduct electrical current to the materials being welded. The design of the electrodes can vary depending on the specific application and the type of metals being joined.

2. Transformer: The transformer reduces the high voltage from the power source to a lower voltage suitable for the welding process while increasing the current.

3. Control System: Modern spot welding machines are equipped with microcontrollers that allow for precise control over the welding parameters, such as current, time, and pressure.

The process begins when the electrodes are positioned on the surfaces to be welded. A current is then passed through the electrodes, generating heat due to electrical resistance at the interface of the metals. This heat raises the temperature to the melting point of the materials, causing them to fuse together. The pressure applied by the electrodes helps ensure a strong bond by minimizing the formation of oxides at the joint.

After a brief cooling period, the welded joint solidifies, resulting in a strong mechanical connection. The entire process is usually very fast, taking only a fraction of a second.

Battery Spot Welding Machine Usage Methods

- Preparation

Before using a battery spot welding machine, it's essential to prepare the workspace and materials:

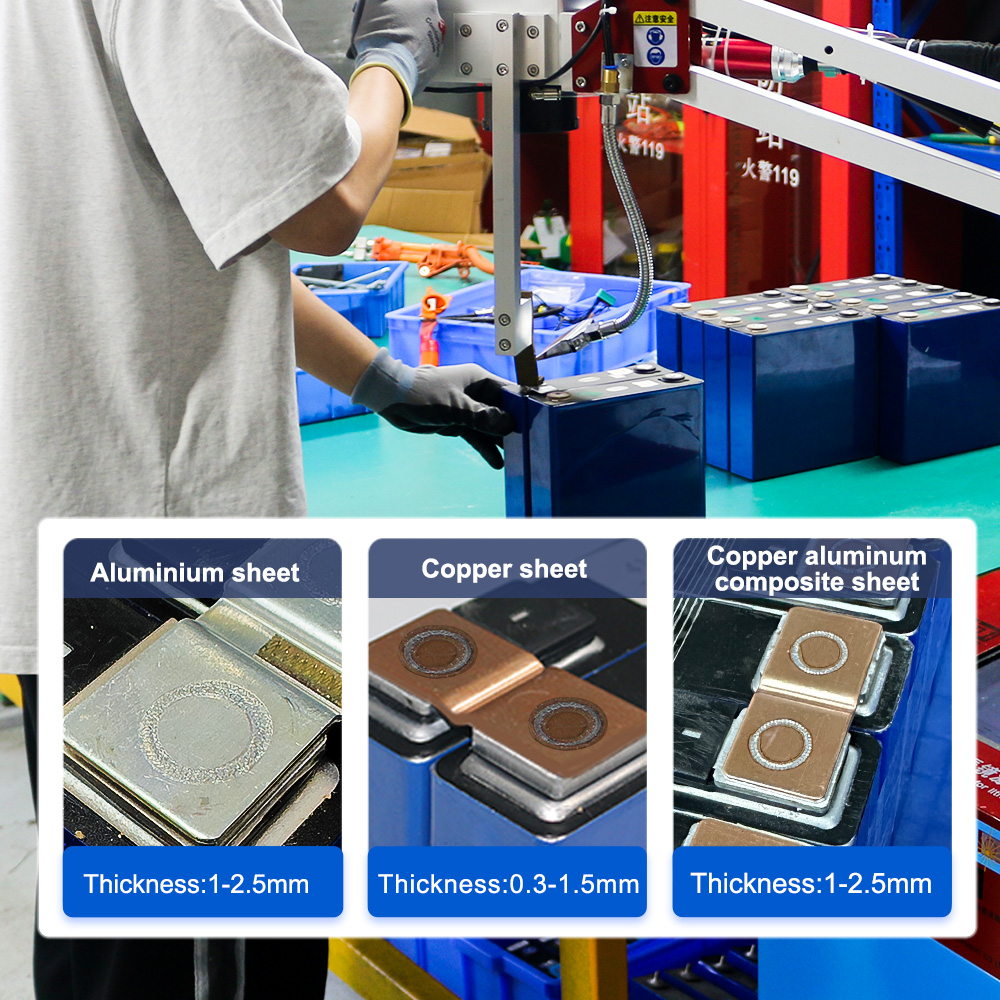

1. Material Selection: Ensure that the metals being welded are compatible. Common materials for battery connections include nickel-plated steel and aluminum.

2. Surface Cleaning: Clean the surfaces to be welded to remove any contaminants, such as grease, dirt, or oxidation. This can be done using solvents or abrasive materials.

3. Equipment Setup: Properly set up the machine according to the manufacturer’s instructions. This includes adjusting the electrodes and ensuring all safety features are operational.

- Spot Welding Machine Welding Process

1. Positioning: Place the battery cells and connecting strips in the correct position between the electrodes. Ensure they are aligned to avoid any misalignment during the welding process.

2. Setting Parameters: Adjust the welding parameters on the control system, including current intensity, welding time, and pressure. These settings may vary based on the materials and thickness being welded.

3. Welding: Activate the machine to begin the welding process. Monitor the operation to ensure that the electrodes maintain proper contact and that the current flows correctly.

4. Inspection: After welding, visually inspect the joints for any defects, such as incomplete fusion or excessive spatter. Some applications may require additional testing for electrical continuity or mechanical strength.

Safety Considerations

Working with spot welding machines can pose certain risks. Always follow safety protocols:

1. Protective Gear: Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and aprons to protect against sparks and heat.

2. Ventilation: Ensure that the workspace is well-ventilated to avoid inhaling any fumes generated during the welding process.

3. Emergency Procedures: Familiarize yourself with emergency shutdown procedures and ensure that the machine has accessible emergency stops.

Conclusion

Battery spot welding machines play a crucial role in the efficient assembly of battery packs. Understanding their working principle and following proper usage methods can lead to high-quality welds and enhanced productivity. By prioritizing safety and preparation, operators can effectively utilize these machines in various applications, contributing to the advancement of energy storage technologies.

If you have the idea of assembling the battery yourself, if you are looking for a high-precision spot welder for your battery welder, then the spot welder from Heltec Energy is worth your consideration.

If you have any questions or would like to learn more, please don't hesitate to reach out to us.

Request for Quotation:

Jacqueline: jacqueline@heltec-energy.com / +86 185 8375 6538

Sucre: sucre@heltec-bms.com / +86 136 8844 2313

Nancy: nancy@heltec-energy.com / +86 184 8223 7713

Post time: Sep-20-2024