Introduction:

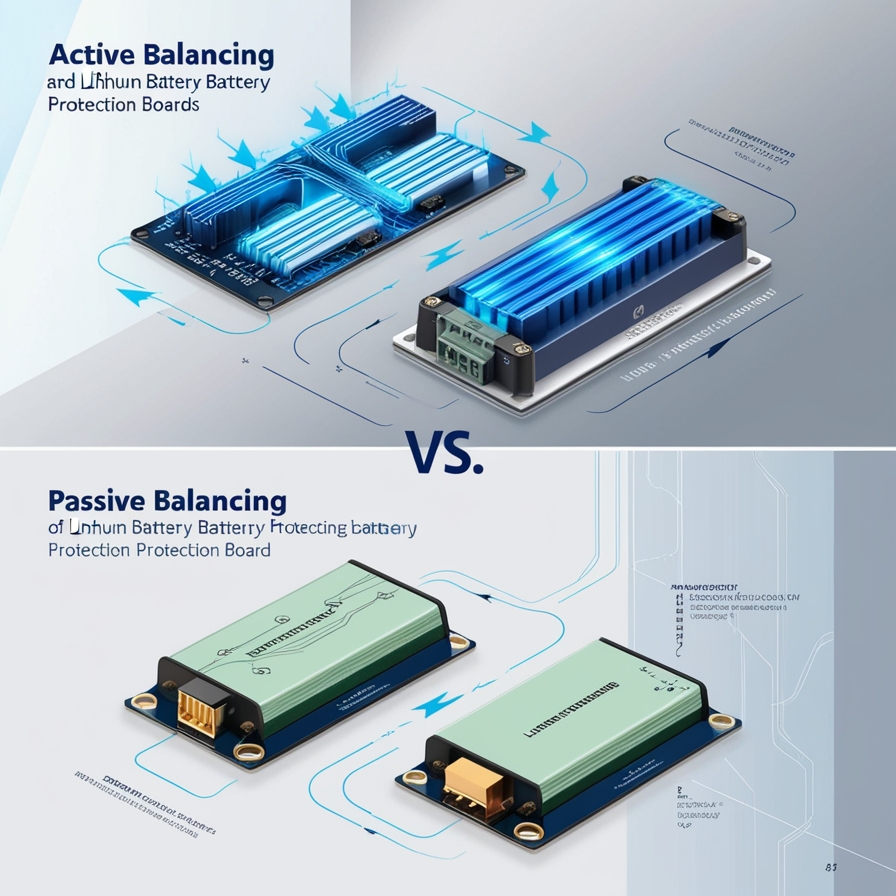

In simple terms, balancing is the average balancing voltage. Keep the voltage of the lithium battery pack consistent. Balancing is divided into active balancing and passive balancing. So what is the difference between active balancing and passive balancing of lithium battery protection board? Let's take a look with Heltec Energy.

Active balancing of lithium battery protection board

Active balancing is that a string with high voltage supplements power to a string with low voltage, so that energy is not wasted, high voltage can be lowered, and low voltage can be supplemented. This kind of active balancing current can choose the balancing current size by yourself. Basically, 2A is commonly used, and there are also large ones with 10A or even higher.

Now the active balancing equipment on the market basically uses the transformer principle, relying on the expensive chips of chip manufacturers. In addition to the balancing chip, there are also expensive peripheral components such as transformers, which are large in size and high in cost.

The effect of active balancing is very obvious: high working efficiency, less energy is converted and not dissipated in the form of heat, and the only loss is the coil of the transformer.

The balancing current can be selected and the balancing speed is fast. Active balancing is more complex in structure than passive balancing, especially the transformer method. The price of BMS with active balancing function will be much higher than that of passive balancing, which also somewhat limits the promotion of active balancing BMS.

Passive balancing of lithium battery protection board

Passive balancing is basically done by adding resistors to discharge. The high-voltage string of cells is discharged in the form of heat dissipation to the surrounding area, achieving the effect of cooling the resistor. The disadvantage is that the discharge is based on the lowest voltage string, and there is a possibility of risk when charging.

Passive balancing is mainly used because of its low cost and simple working principle; its disadvantage is that it is balanced based on the lowest power, and cannot supplement the low-voltage string, resulting in energy waste.

The difference between active balancing and passive balancing

Passive balancing is suitable for small-capacity, low-voltage lithium batteries, while active balancing is suitable for high-voltage, large-capacity power lithium battery pack applications.

Commonly used balancing charging technologies include constant shunt resistor balancing charging, on-off shunt resistor balancing charging, average battery voltage balancing charging, switch capacitor balancing charging, buck converter balancing charging, inductor balancing charging, etc. When charging a group of lithium batteries in series, each battery should be charged evenly, otherwise the performance and life of the entire battery group will be affected during use.

| Features | Passive balancing | Active balancing |

| Working principle | Consume excess power through resistors | Balance battery power through energy transfer |

| Energy loss Large | energy wasted as heat Small | efficient transfer of electrical energy |

| Cost | Low | High |

| Complexity | Low, mature technology | High, complex circuit design required |

| Efficiency | Low, heat loss | High, almost no energy loss |

| Applicable | scenarios Small battery packs or low-cost applications | Large battery packs or high-performance applications |

.jpg)

The basic principle of passive balancing is to achieve the balancing effect by wasting excess power. Usually, the excess power in the overvoltage battery pack is converted into heat through a resistor, so that the battery voltage remains consistent. The advantage is that the passive balancing circuit is simple and the design and implementation cost is low. And the passive balancing technology is very mature and has been widely used in many low-cost and small battery packs.

The disadvantage is that there is a large energy loss due to the conversion of electrical energy into heat through resistance. Low efficiency, especially in large-capacity battery packs, energy waste is more obvious, and it is not suitable for large-scale, high-performance battery applications. And because the electrical energy is converted into heat, it may cause the battery pack to overheat, affecting the safety and life of the overall system.

Active balancing achieves balancing by transferring excess electrical energy from batteries with higher voltage to batteries with lower voltage. This method generally adjusts the power distribution between batteries through switching power supplies, buck-boost converters or other electronic components. The advantage is high efficiency: energy is not wasted, but balanced by transfer, so there is no heat loss, and the efficiency is usually high (up to 95% or more).

Energy saving: Since there is no energy waste, it is suitable for large-capacity, high-performance lithium battery systems and can extend the service life of the battery pack. Applicable to large battery packs: Active balancing is more suitable for large-capacity battery packs, especially in scenarios such as electric vehicles and energy storage systems, and can significantly improve system efficiency and endurance.

The disadvantage is that the design and implementation of active balancing is relatively complex, usually requiring more electronic components, so the cost is higher. Technical complexity: Precision control and circuit design are required, which is difficult and may increase the difficulty of development and maintenance.

Conclusion

If it is a low-cost, small system or an application with low requirements for balancing, passive balancing can be selected; for battery systems that require efficient energy management, large capacity or high performance, active balancing is a better choice.

Heltec Energy is a company that develops and manufactures high-performance battery testing and repair equipment, and provides solutions for back-end manufacturing, pack assembly production, and old battery repair for lithium batteries.

Heltec Energy has always insisted on independent innovation, with the main goal of providing reliable and highly cost-effective products in the lithium battery industry, and with the service concept of "customer first, quality excellence" to create value for customers. During its development, the company has a team of senior engineers in the industry, which effectively guarantees the advancement and practicality of its products.

If you have any questions or would like to learn more, please don't hesitate to reach out to us.

Request for Quotation:

Jacqueline: jacqueline@heltec-energy.com / +86 185 8375 6538

Sucre: sucre@heltec-bms.com / +86 136 8844 2313

Nancy: nancy@heltec-energy.com / +86 184 8223 7713

Post time: Nov-26-2024