Introduction:

Heltec point welding machine SW02 series has high-frequency inverter super-energy storage capacitor discharge welder, eliminates interference to AC power supply, and avoid switch tripping situation. This series spot welding machine is equipped with Chinese patented energy storage control and low-loss metal busbar technology to ensure maximum burst energy output. Microcomputer chip-controlled energy-concentrated pulse forming technology ensures reliable welds within milliseconds, while intelligent programs and multi-function parameter display provide clear and efficient welding management.

HT-SW02 series point welding machine with dual-mode spot welding to achieve precise, fast and efficient welding, which is convenient for welding different weldments. The unique real-time display of welding pulse current can monitor each welding current and avoid false welding of solder joints. The machine is designed with ultra-low loss and high-efficiency performance in mind. Its professional, industrial-grade manufacturing ensures the machine without getting hot even during extended use, making it a reliable and durable tool for all your welding needs.

Current and Power:

HT-SW02A point welding machine Output Current is 6000A(Peak), the Pulse Power 36KW(Peak)

HT-SW02H point welding machine Output Current is 7000A(Peak), the Pulse Power 42KW(Peak)

| Model | HT-SW02A | HT-SW02H |

| Power Supply | AC 110V and 220V optional | AC 110V and 220V optional |

| Pulse Power | 36KW | 42KW |

| Energy Grade | 0-99T(0.2ms/T) | 0-99T(0.2ms/T) |

| Pulse Time | 0~20ms | 0~20ms |

| Output Current | 6000A(Peak) | 7000A(Peak) |

| Output Voltage | 5.6-6.0V | 5.6-6.0V |

| Dimension | 24(L)x14(W)x21(H)cm | 24(L)x14(W)x21(H)cm |

| Charging Current | 10-20A | 10-20A |

| Peak Welding Energy | 720J | 840J |

| Welding Mode | MT:Foot control mode AT:Automatic welding mode | MT:Foot control mode AT:Automatic welding mode |

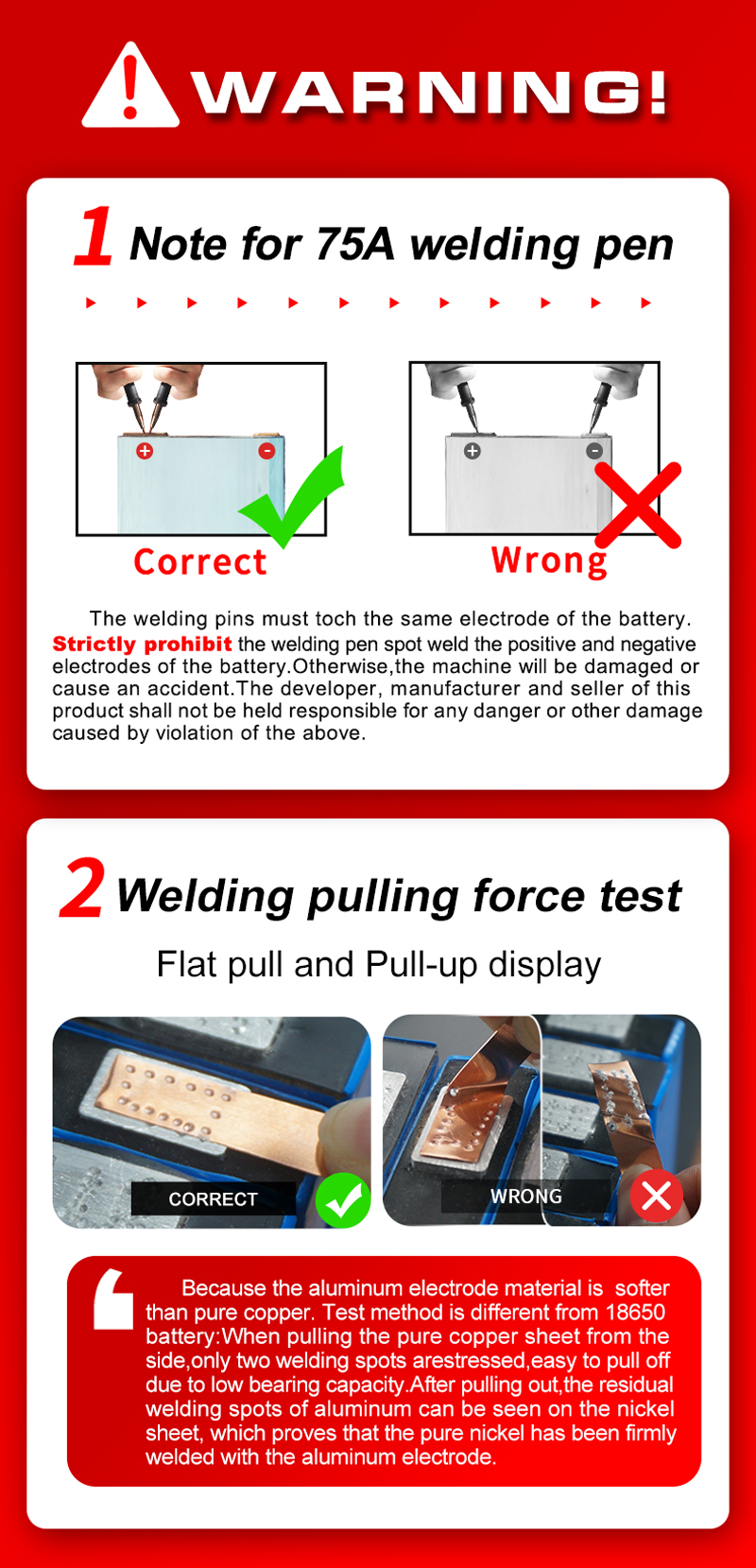

| Welding Tool | 75A Split spot welding pen | 75ASplit spot welding pen |

| AT Preloading Delay | 300ms | 300ms |

| Charging Time | About 18 min | About 18 min |

| Welding Thickness | 0.1~0.3mm Copper (with flux) 0.1-0.5mm Pure nickel | 0.1~0.4mm Copper(with flux)0.1~0.6mm Pure nickel |

| Net Weight | 6.5 KG | 6.5KG |

Applications:

The point welder HT-SW02 series point welding machine have the similar applications:

- Spot welding of Lithium iron phosphate battery, Ternary lithium battery, nickel steel, o Assemble or repair battery packs and portable sources.

- Production of small battery packs for mobile electronic devices.

- Welding of lithium polymer battery, cell phone battery, and protective circuit board.

- Spot welding leaders to different metal projects, such as iron, stainless steel, brass, nickel, molybdenum and titanium.

Function Features:

The biggest functional difference between the two SW02 series spot welders is that the SW02H can test resistance in addition to spot welding, while the SW02A can only spot welding.

| Model | Accessory | Material and thickness(MAX) | Function | Apply Battery Type |

| HT- SW02A |

1. 75A 35² spot welding pen | Copper with flux: 0.3mm Aluminum nickel composite slice: 0.3mm Pure nickel: 0.4mm Nickelage: 0.6mm |

Spot welding | Copper sheet, 18650, 21700, 26650, 32650 battery, Lithium iron phosphate |

| HT- SW02H |

1. 75A 50² spot welding pen 2.Milliohm resistance measuring pen |

Copper with flux: 0.5mm Aluminum nickel composite slice: 0.4mm Pure nickel: 0.4mm Nickelage: 0.6mm |

1.Spot welding 2.Resistance measurement |

Copper sheet, 18650, 21700, 26650, 32650 battery, Lithium iron phosphate |

Conclusion

Experience the next level of welding technology with Heltec high-frequency inverter super energy storage capacitor discharge welder. Whether you're working with delicate materials or heavy-duty applications, this welder is designed to meet your welding needs with precision, efficiency, and reliability.

If you have any questions or would like to learn more, please don't hesitate to reach out to us.

Request for Quotation:

Jacqueline: jacqueline@heltec-bms.com / +86 185 8375 6538

Sucre: sucre@heltec-bms.com / +86 136 8844 2313

Nancy: nancy@heltec-bms.com / +86 184 8223 7713

Post time: Aug-09-2024