Introduction:

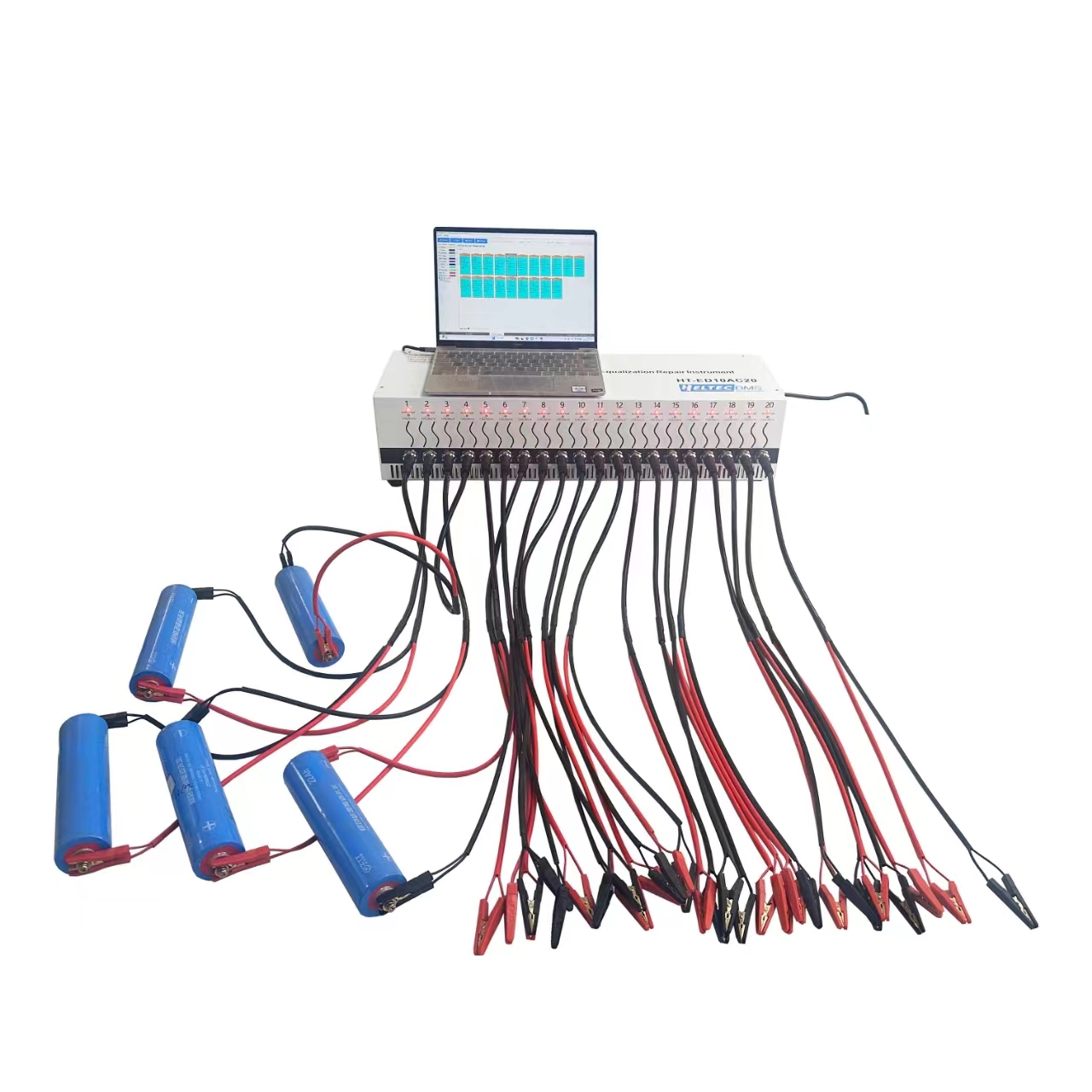

Welcome to the official Heltec Energy product blog! We’re glad to introduce you to our company’s new product -- lithium battery charge and discharge equalization repair instrument, a cutting-edge solution designed to optimize the battery production process. This innovative instrument simplifies the capacity testing and consistency screening processes, merging them into one automated program. The instrument relies on advanced technology to ensure efficient and accurate testing, judgment and classification of battery performance.

Breakthrough:

- Traditional production process:

- Improved production process:

The isolation detection technology of the Battery Repair Instrument can directly conduct charge and discharge tests on the cells of the entire battery pack without disassembling the battery pack, find out the bad cells, and replace them accurately to improve maintenance efficiency without disassembly.

Feature:

- Each channel is equipped with a dedicated processor to ensure perfect capacity calculation, timing, voltage and current control.

- Full channel isolation test, can directly test the whole battery cell.

- Single 5V/10A charge/discharge power.

- Fully compatible with lithium iron phosphate, lithium ternary, lithium cobaltate, NiMH, NiCd and other types of batteries.

- 18650, 26650 LiFePO4, No.5 Ni-MH batteries, pouch batteries, prismatic batteries, single large batteries and other battery connections.

- Independent air ducts for heat sources, temperature-controlled speed-controlled fans.

- Cell test probe height adjustable, scale scale for easy leveling.

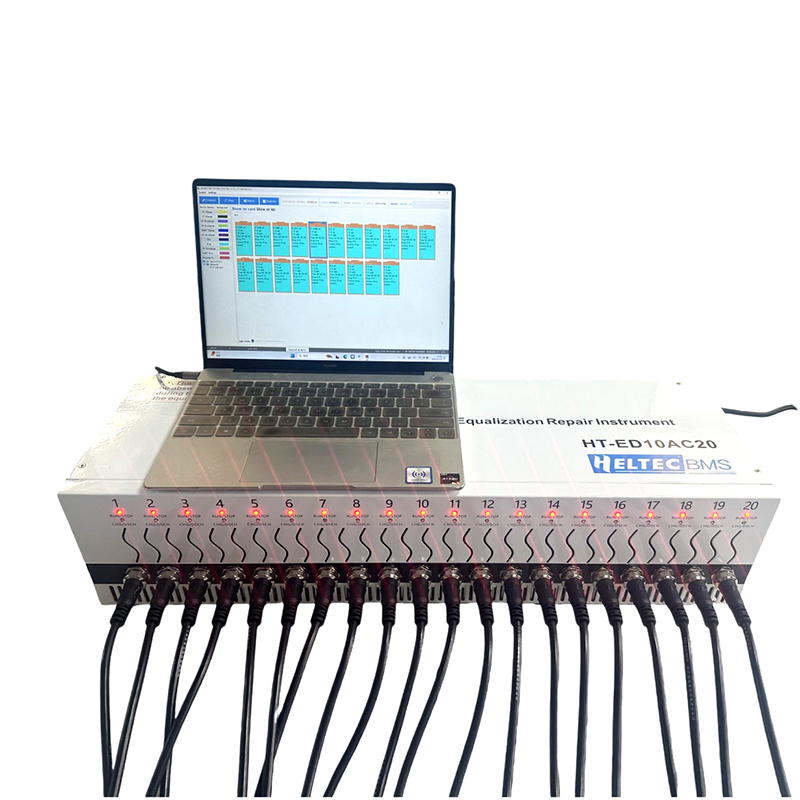

- Operation detection status, grouping status, alarm status LED indication.

- PC online device testing, detailed and rich test settings and results.

- With CC constant current discharge, CP constant power discharge, CR constant resistance discharge, CC constant current charge, CV constant voltage charge, CCCV constant current and constant voltage charge, shelving and other test steps can be called.

- Customizable charging or discharging parameters; e.g. charging voltage.

- With work-step jumping capability.

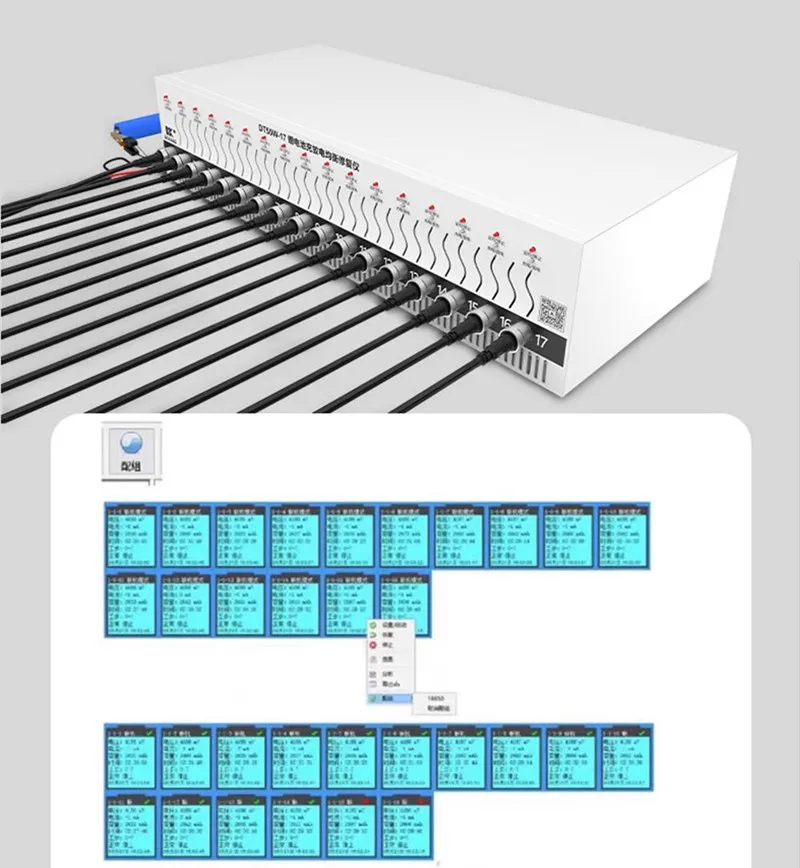

- Can implement the grouping function, test results are grouped according to custom criteria and marked on the device to display the function.

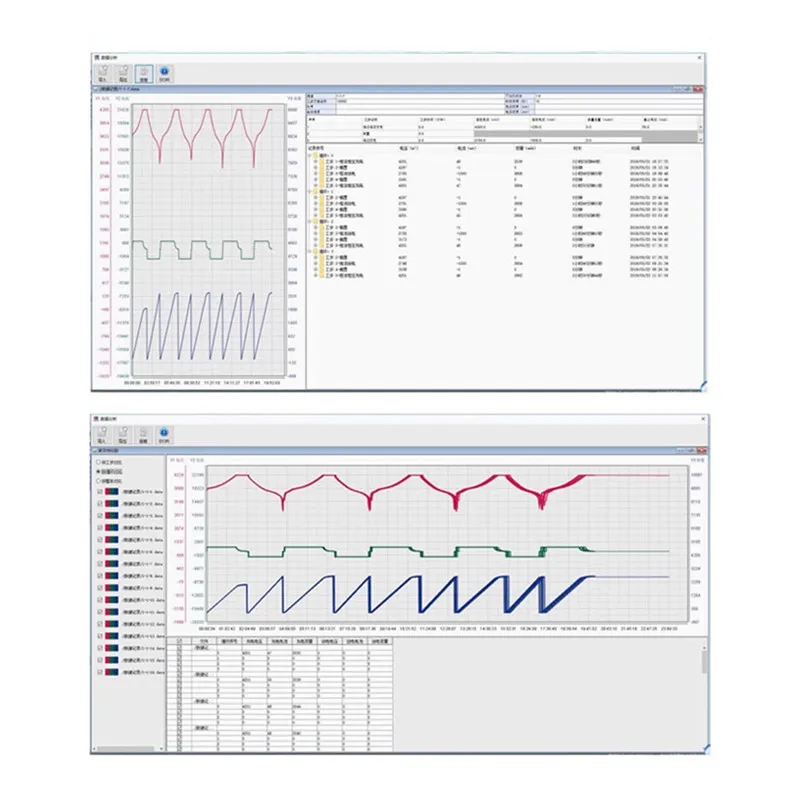

- With test process data recording function.

- With 3 Y-axis (voltage, current, capacity) a time axis curve drawing capability, and data report function.

- Test status pane color customization, when the number of tests is large, you can easily visualize the detection status of all devices.

Product Parameters:

| Input power | AC200V~245V @50HZ/60HZ |

| Standby power | 80W |

| Full load power | 1650W |

| Allowable temperature and humidity | Ambient temperature <35 degrees;Humidity <90% |

| Number of channels | 20 |

| Inter-channel voltage resistance | AC1000V/2min without abnormality |

| Maximum charging current | 10A |

| Maximum discharge current | 10A |

| Maximum output voltage | 5V |

| Minimum voltage | 1V |

| Measurement voltage accuracy | ±0.02V |

| Measuring current accuracy | ±0.02A |

| Applicable systems and configurations of the upper computer software | Windows XP or above systems with network port configuration. |

Conclusion:

The instrument is capable of handling various types and sizes of lithium batteries, making it a versatile solution for different production needs. Whether in small-scale or large-scale production, the instrument delivers consistent, reliable results, ensuring only the highest quality batteries reach the market.

In summary, lithium battery charge and discharge equalizers represent a significant advancement in battery testing and quality control. Its ability to streamline production processes, improve efficiency and enhance battery performance makes it an indispensable tool for manufacturers. With its advanced features and user-friendly design, this instrument sets a new standard for industry battery testing and optimization.

If you have any questions or would like to learn more, please don't hesitate to reach out to us.

Post time: Jun-21-2024