Introduction:

Lithium batteries are a type of battery that uses lithium metal or lithium alloy as the negative electrode material and a non-aqueous electrolyte solution. Due to the highly active chemical properties of lithium metal, the processing, storage and use of lithium metal have very high environmental requirements. Next, let's take a look at the processes of welding caps, cleaning, dry storage, and alignment inspection in the preparation of lithium batteries.

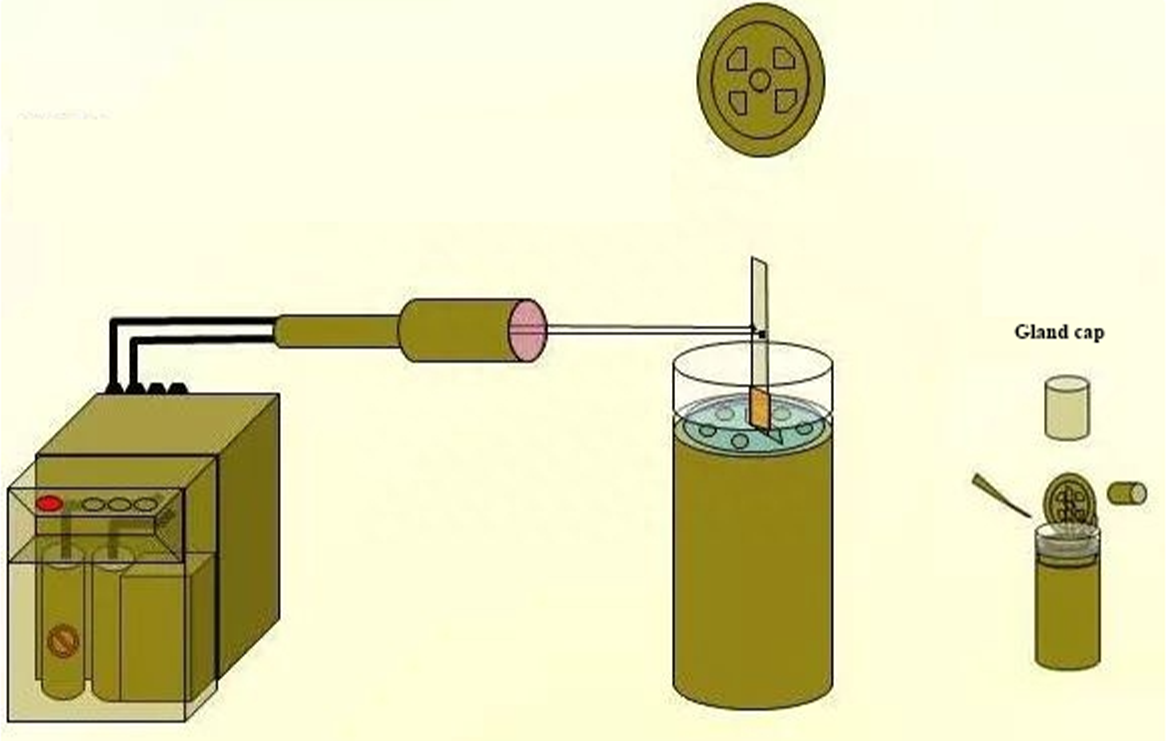

Welding Cap for Lithium Battery

The functions of lithium battery cap:

1) positive or negative terminal;

2) temperature protection;

3) power-off protection;

4) pressure relief protection;

5) sealing function: waterproof, gas intrusion, and electrolyte evaporation.

The key points for welding caps:

Welding pressure is greater than or equal to 6N.

Welding appearance: no false welds, weld coke, weld penetration, weld slag, no tab bending or breakage ect.

Production process of welding cap

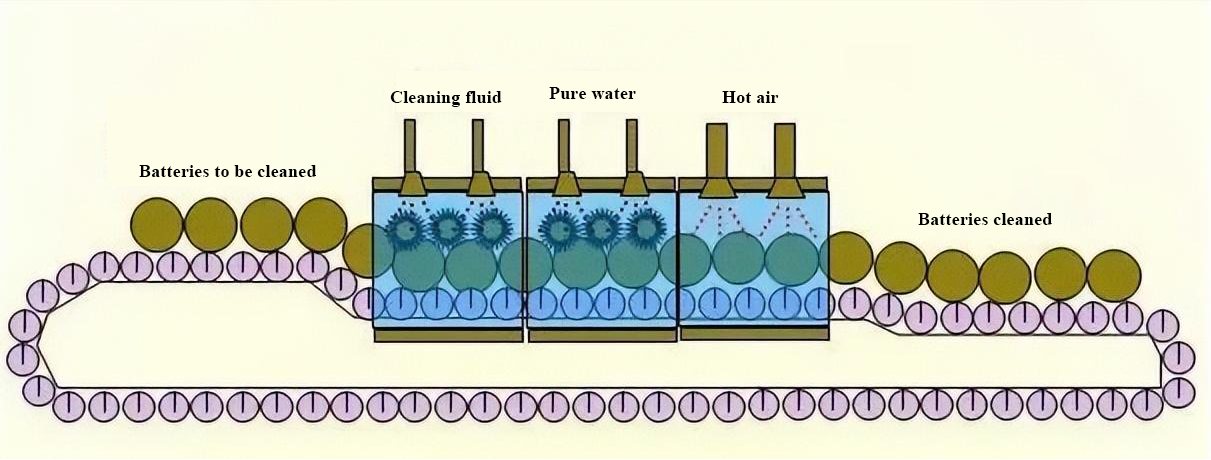

Cleaning the Lithium Battery

After the lithium battery is sealed, electrolyte or other organic solvents will remain on the surface of the shell, and the nickel plating (2μm~5μm) at the seal and bottom welding is easy to fall off and rust. Therefore, it needs to be cleaned and rust-proofed.

Cleaning production process

1) Spray and clean with sodium nitrite solution;

2) Spray and clean with deionized water;

3) Blow dry with an air gun, dry at 40℃~60℃; 4) Apply anti-rust oil.

Dry storage

Lithium batteries should be stored in a cool, dry and safe environment. They can be stored in a clean, dry and ventilated environment with a temperature of -5 to 35°C and a relative humidity of no more than 75%. Note that storing batteries in a hot environment will inevitably cause corresponding damage to the quality of the batteries.

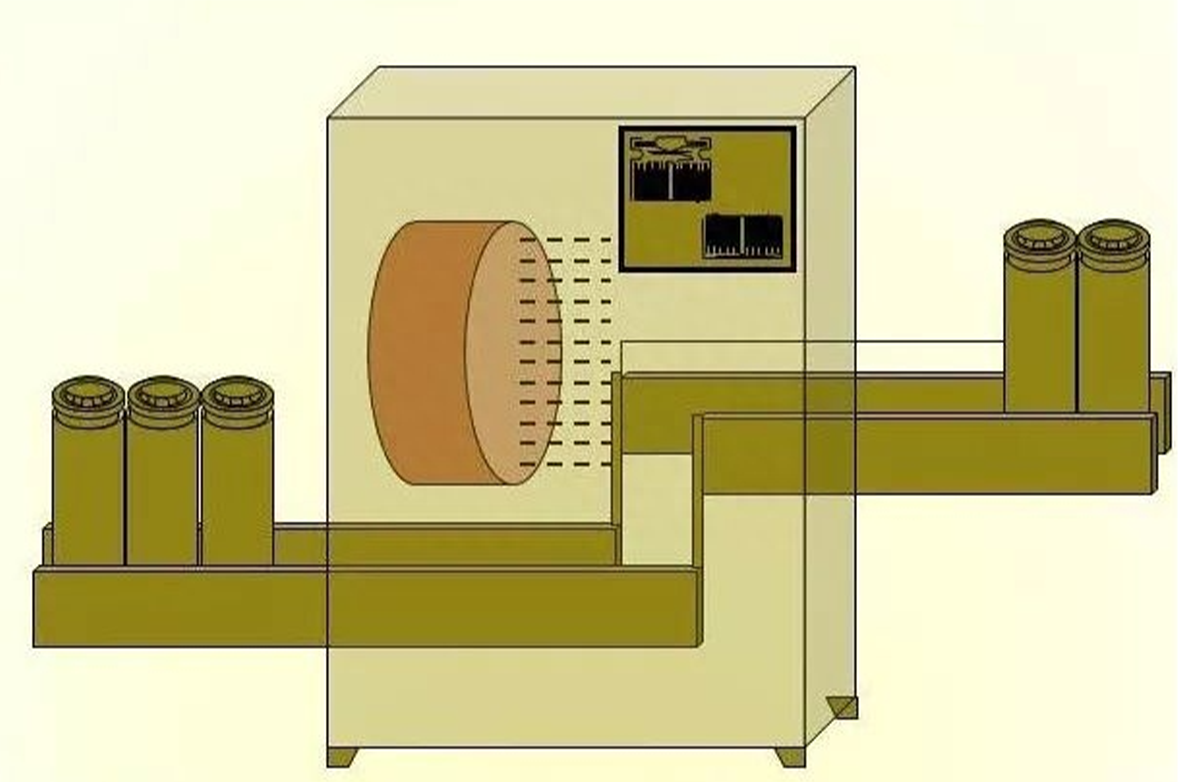

Detecting alignment

In the production process of lithium batteries, corresponding testing equipment is often used to ensure the yield of finished batteries, avoid battery safety accidents, and thus improve production efficiency.

Detecting the alignment of lithium battery cells is of utmost importance. The cell is equivalent to the heart of the lithium battery. It is mainly composed of positive electrode materials, negative electrode materials, electrolytes, diaphragms and shells. When external short circuits, internal short circuits and overcharge occur, the lithium battery cells will have the risk of explosion.

Conclusion

The preparation of lithium batteries is a complex multi-step process, and each link requires strict control of raw material quality and production processes to ensure the performance, safety and life of the final battery product.

Heltec Energy is your trusted partner in battery pack manufacturing. With our relentless focus on research and development, coupled with our comprehensive range of battery accessories, we offer one-stop solutions to meet the evolving needs of the industry. Our commitment to excellence, tailored solutions, and strong customer partnerships make us the go-to choice for battery pack manufacturers and suppliers worldwide.

If you have any questions or would like to learn more, please don't hesitate to reach out to us.

Request for Quotation:

Jacqueline: jacqueline@heltec-energy.com / +86 185 8375 6538

Sucre: sucre@heltec-bms.com / +86 136 8844 2313

Nancy: nancy@heltec-energy.com / +86 184 8223 7713

Post time: Nov-05-2024