Introduction:

Lithium battery is a rechargeable battery with lithium as the main component. It is widely used in various electronic devices and electric vehicles due to its high energy density, light weight and long cycle life. Regarding the processing of lithium batteries, let's take a look at the processes of spot welding, core baking and liquid injection of lithium batteries.

Spot welding

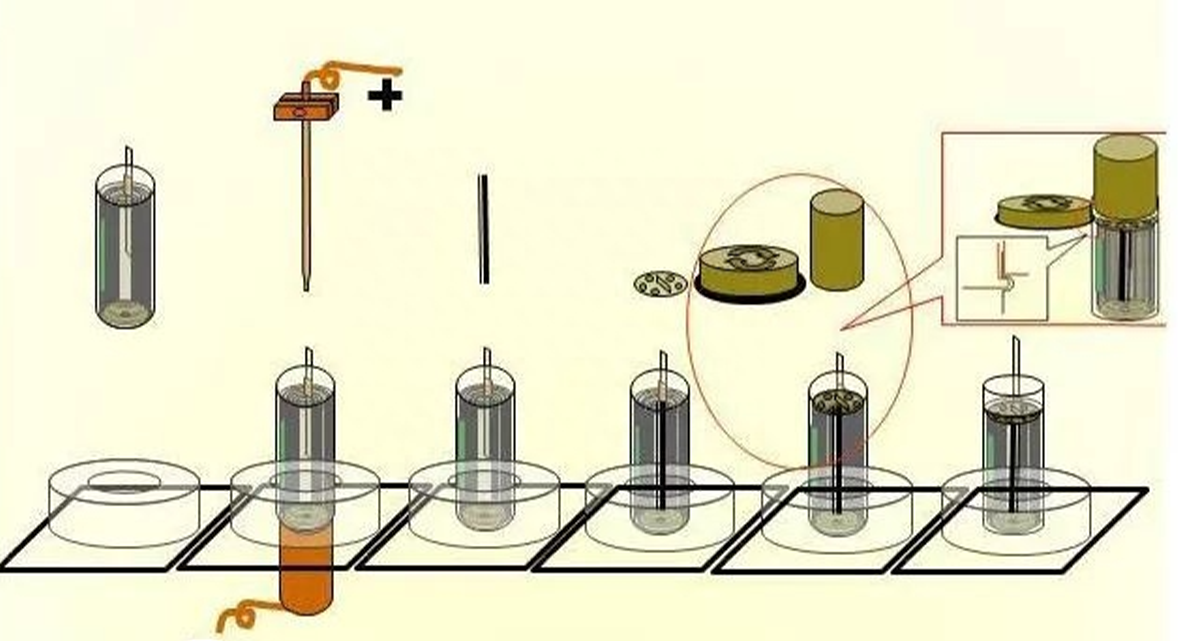

Welding between the poles of lithium batteries and between the poles and the electrolyte conductor is one of the important processes in lithium battery manufacturing. Its main principle is to use a high-frequency pulse arc to apply an instantaneous high-temperature and high-voltage current between the pole and the electrolyte conductor, so that the electrode and the lead quickly melt and form a firm connection. During the welding process, welding parameters such as welding temperature, time, pressure, etc. need to be strictly controlled to ensure welding quality.

Spot welding is a traditional welding method and is currently the most widely used welding method. Using the principle of resistance heating, the welding material heats up and melts through the interaction of current and resistance, forming a strong connection. Spot welding is suitable for the manufacture of large battery components, such as electric vehicle batteries, energy storage batteries, etc.

Baking of battery cells

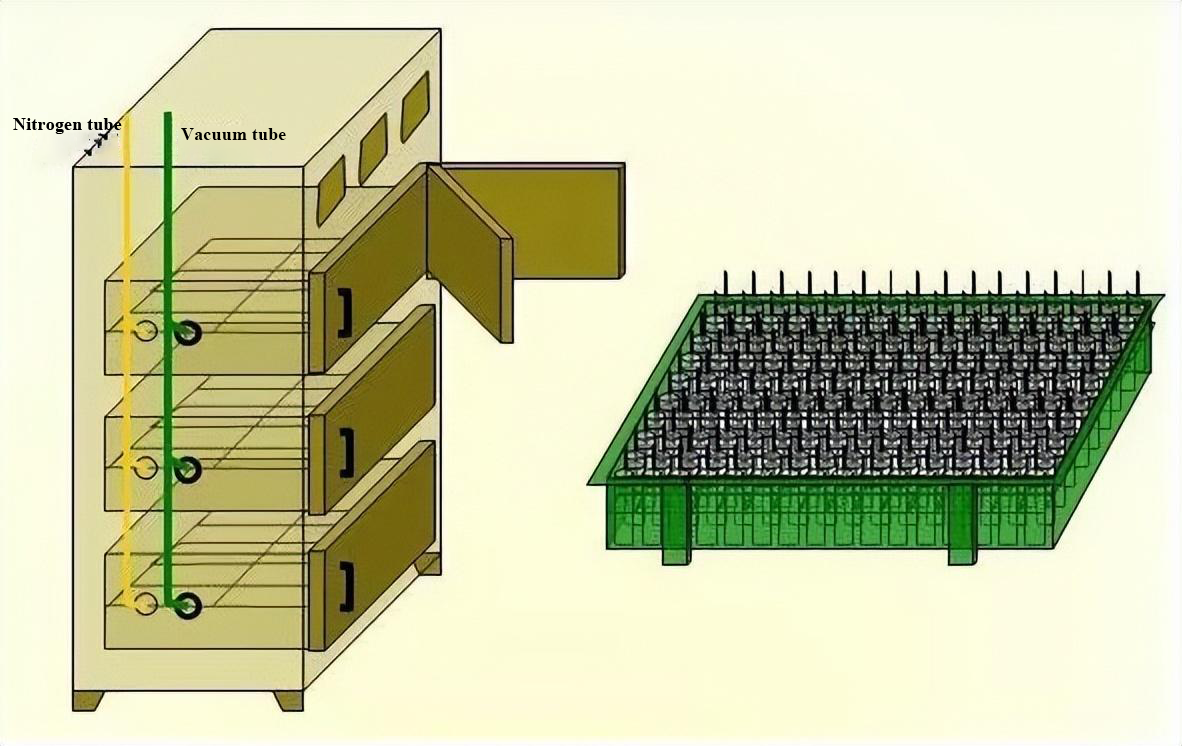

Baking plays a vital role in the production of lithium battery cells. The water content after baking directly affects the electrical performance. The baking process is after the middle assembly and before the liquid injection and packaging.

The baking process generally adopts a vacuum baking method, pumping the cavity to negative pressure, and then heating to a certain temperature for insulation baking. The moisture inside the electrode diffuses to the surface of the object through pressure difference or concentration difference. The water molecules obtain enough kinetic energy on the surface of the object, and after overcoming the intermolecular attraction, they escape into the low pressure of the vacuum chamber.

Injection

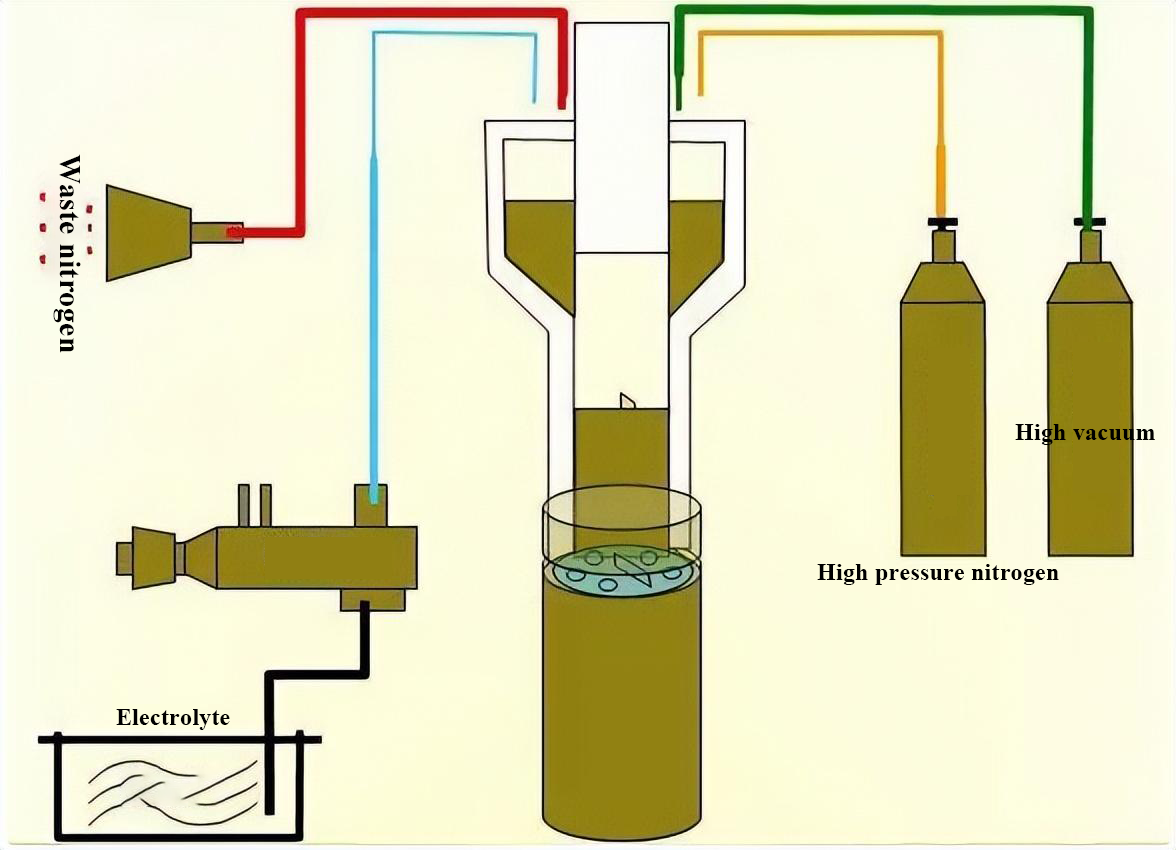

The role of lithium battery electrolyte is to conduct ions between the positive and negative electrodes, and act as a medium for charging and discharging, just like human blood. The role of the electrolyte is to conduct ions, ensuring that the ions move at a certain rate between the positive and negative electrodes during the battery charging and discharging process, thereby forming the entire circuit loop to generate current.

Injection has a relatively large impact on the performance of the battery cell. If the electrolyte is not well infiltrated, it will cause poor battery cell cycle performance, poor rate performance, and charging lithium deposition. Therefore, after injection, it is necessary to stand at high temperature to allow the electrolyte to fully infiltrate the electrode.

Injection production process

Injection is to first evacuate the battery and use the pressure difference between the inside and outside of the battery cell to drive the electrolyte into the battery cell. Isobaric injection is to first use the differential pressure principle to inject liquid, and then move the injected battery cell to a high-pressure container, and pump negative pressure/positive pressure to the container for static circulation.

Heltec offers various types of high-performance spot welders designed specifically for battery metal welding. Using advanced resistance welding technology, it has fast welding speed and high weld strength, suitable for welding batteries and electronic products. Equipped with an intelligent control system, users can easily adjust welding parameters to ensure consistent welding quality. Our series of spot welders are compact and easy to operate, helping to improve production efficiency and reduce energy consumption. Choose us to help you achieve efficient welding solutions!

Conclusion

Every step in the lithium battery processing process needs to be strictly controlled to ensure the safety and performance of the final product. With the advancement of technology, many companies are also constantly exploring new materials and processes to improve the energy density and service life of batteries.

Heltec Energy is your trusted partner in battery pack manufacturing. With our relentless focus on research and development, coupled with our comprehensive range of battery accessories, we offer one-stop solutions to meet the evolving needs of the industry. Our commitment to excellence, tailored solutions, and strong customer partnerships make us the go-to choice for battery pack manufacturers and suppliers worldwide.

If you have any questions or would like to learn more, please don't hesitate to reach out to us.

Request for Quotation:

Jacqueline: jacqueline@heltec-energy.com / +86 185 8375 6538

Sucre: sucre@heltec-bms.com / +86 136 8844 2313

Nancy: nancy@heltec-energy.com / +86 184 8223 7713

Post time: Nov-01-2024