Introduction:

Heltec SW01 series battery welding machine is an industry game changer, providing a reliable and efficient solution for battery welding. Unlike traditional AC spot welders, the capacitor energy storage design eliminates interference and tripping issues, ensuring a seamless welding process. Heltec spot welding machine adopts the latest energy-gathered pulse welding technology,it has a great welding power,the welding spot is nice and elegant,ensuring you a reliable welding effect. Applicable to spot welding of various batteries, battery packs and different metal materials. We have five products in the 01 series, each with unique characteristics, so it’s important to understand the differences to make an informed choice.

Specifications:

- HT-SW01A Spot Welding Machine

- HT-SW01A+ Spot Welding Machine

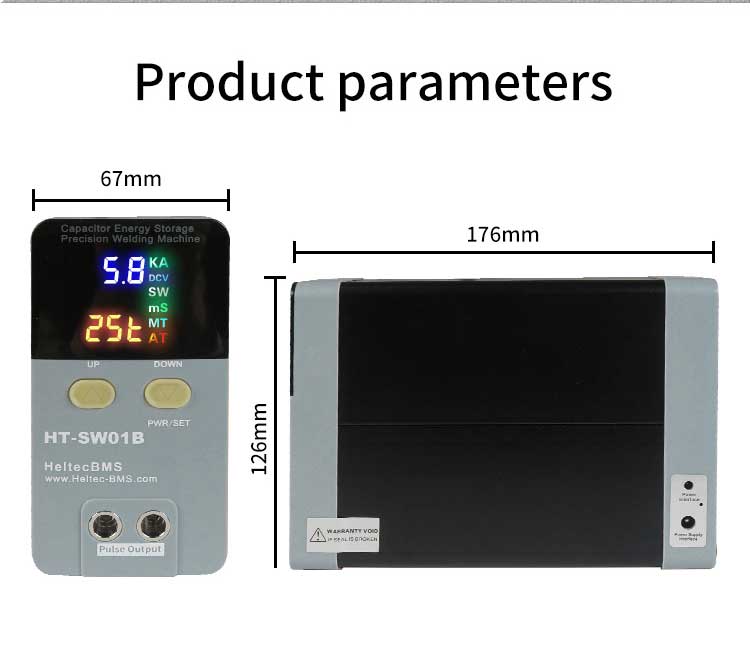

- HT-SW01B Spot Welding Machine

- HT-SW01D Spot Welding Machine

- HT-SW01H Spot Welding Machine

Similar Application:

The SW01 series spot welding machine all can be used to:

1. Spot welding of Lithium iron phosphate battery, Ternary lithium battery, nickel steel.

2. The spot welding machine assemble or repair battery packs and portable sources.

3. Production of small battery packs for mobile electronic devices.

4. Welding of lithium polymer battery, cell phone battery, and protective circuit board.

5. The battery welder leaders to different metal projects, such as iron, stainless steel, brass, nickel, molybdenum and titanium.

Performance Comparison:

| Picture |  |

|

|

|

|

| SKU | HT-SW01A | HT-SW01A+ | HT-SW01B | HT-SW01D | HT-SW01H |

| Principle | DC energy storage | DC energy storage | DC energy storage | DC energy storage | DC energy storage |

| Output Power | 11.6KW | 11.6KW | 11.6KW | 14.5KW | 21KW |

| Output Current | 2000A (Max.) | 2000A (Max.) | 2000A (Max.) | 2500A (Max.) | 3500A (Max.) |

| Standard Welding Tools | 1.70A(16mm²) split welding pen; 2.Metal butt welding seat. |

1.70B(16mm²) integrated welding pen; 2.73SA Press down spot welding head. |

1.70B(16mm²) integrated welding pen; 2.73SA Press down spot welding head. |

1.73B(16mm²) integrated welding pen; 2.73SA Press down spot welding head. |

1.75 (25mm²) split welding pen; 2.73SA Press down spot welding head. |

| Pure nickel welding 18650 thickness |

0.1~0.15mm | 0.1~0.15mm | 0.1~0.2mm | 0.1~0.3mm | 0.1~0.4mm |

| Nickel plating welding 18650 thickness |

0.1~0.2mm | 0.1~0.25mm | 0.1~0.3mm | 0.15~0.4mm | 0.15~0.5mm |

| Pure nickel welding LFP aluminum electrode |

/ | / | / | / | / |

| Nickel aluminum composite sheet welding LFP aluminum electrode |

/ | / | / | / | 0.1~0.15mm |

| Copper welding LFP Copper electrode (with flux) | / | / | / | / | / |

| Power Supply | AC 110~220V (general) |

AC 110~220V (general) |

AC 110~220V (general) |

AC 110~220V (general) |

AC 110~220V (general) |

| Output Voltage | DC 5.3V(Max.) | DC 6.0V(Max.) | DC 6.0V(Max.) | DC 6.0V(Max.) | DC 6.0V(Max.) |

| Energy Storage Charging Current | 2.8A(Max.) | 2.8A(Max.) | 4.5A(Max.) | 4.5A(Max.) | 6A(Max.) |

| First Charging Time | 30~40 min | 30~40 min | 30~40 min | 30~40 min | About 18 min |

| Trigger Mode | AT: Automatic induction trigger | AT: Automatic induction trigger | AT: Automatic induction trigger MT: Foot pedal trigger |

AT: Automatic induction trigger MT: Foot pedal trigger |

AT: Automatic induction trigger MT: Foot pedal trigger |

| Model | HT-SW01A | HT-SW01A+ | HT-SW01B | HT-SW01D | HT-SW01H |

| 73SA Down Pressing Rocker Arm | × | √ | √ | √ | √ |

| Standard Welding Pen Model |

70A Separate | 70BN Integrated | 70BN Integrated | 73B Integrated |

75A(25mm) Split |

| Pure Nickel Welding to LFP on Aluminum Electrode |

× | × | × | × | √ |

| Pure Nickel THK (Welding Pen) | ≤0.2mm | ≤0.25mm | ≤0.25mm | ≤0.3mm | ≤0.4mm |

| Nickelage/Stainless Steel THK (Welding Pen) | ≤0.25~0.3mm | ≤0.3mm | ≤0.3mm | ≤0.4mm | ≤0.5mm |

| Pulse Time (Max) | 5ms | 10ms | 10ms | 20ms | 20ms |

| MT Pedal Precision Spot Welding |

× | × | √ | √ | √ |

| AT Auto Trigger Spot Welding |

√ | √ | √ | √ | √ |

| Voltage Test Function | × | √ | × | × | × |

| Real Welding Current Display |

× | × | √ | √ | √ |

| Memory Function | × | × | × | √ | √ |

Conclusion

Heltec SW01 series spot welding machine represents a significant advancement in battery welding technology. By addressing the limitations of traditional AC spot welding machines, it offers a reliable and efficient solution for achieving high-quality welds. With five distinct products in the 01 series, each with its own unique characteristics, users have the opportunity to select a spot welding machine that best aligns with their specific requirements. Whether it's precision, control, or user-friendly design, the SW01 series spot welding machine is poised to elevate the battery welding experience.

After reading the above description, I believe you can also clearly understand the characteristics of each spot welding machine. Hope it can help you choose your favorite machine. If you have any questions or would like to learn more, please don't hesitate to reach out to us.

Request for Quotation:

Jacqueline: jacqueline@heltec-bms.com / +86 185 8375 6538

Sucre: sucre@heltec-bms.com / +86 136 8844 2313

Nancy: nancy@heltec-bms.com / +86 184 8223 7713

Post time: Aug-08-2024