Introduction:

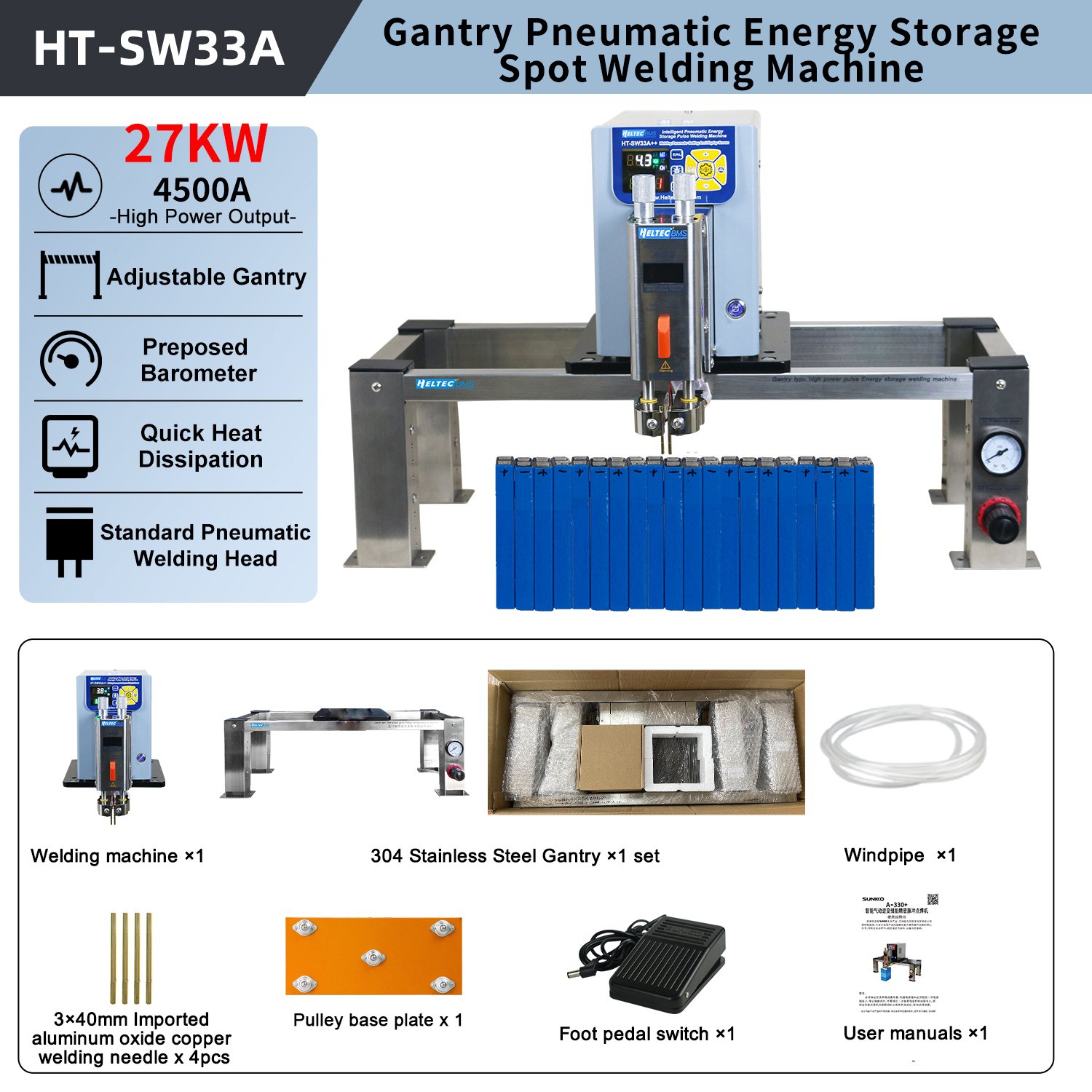

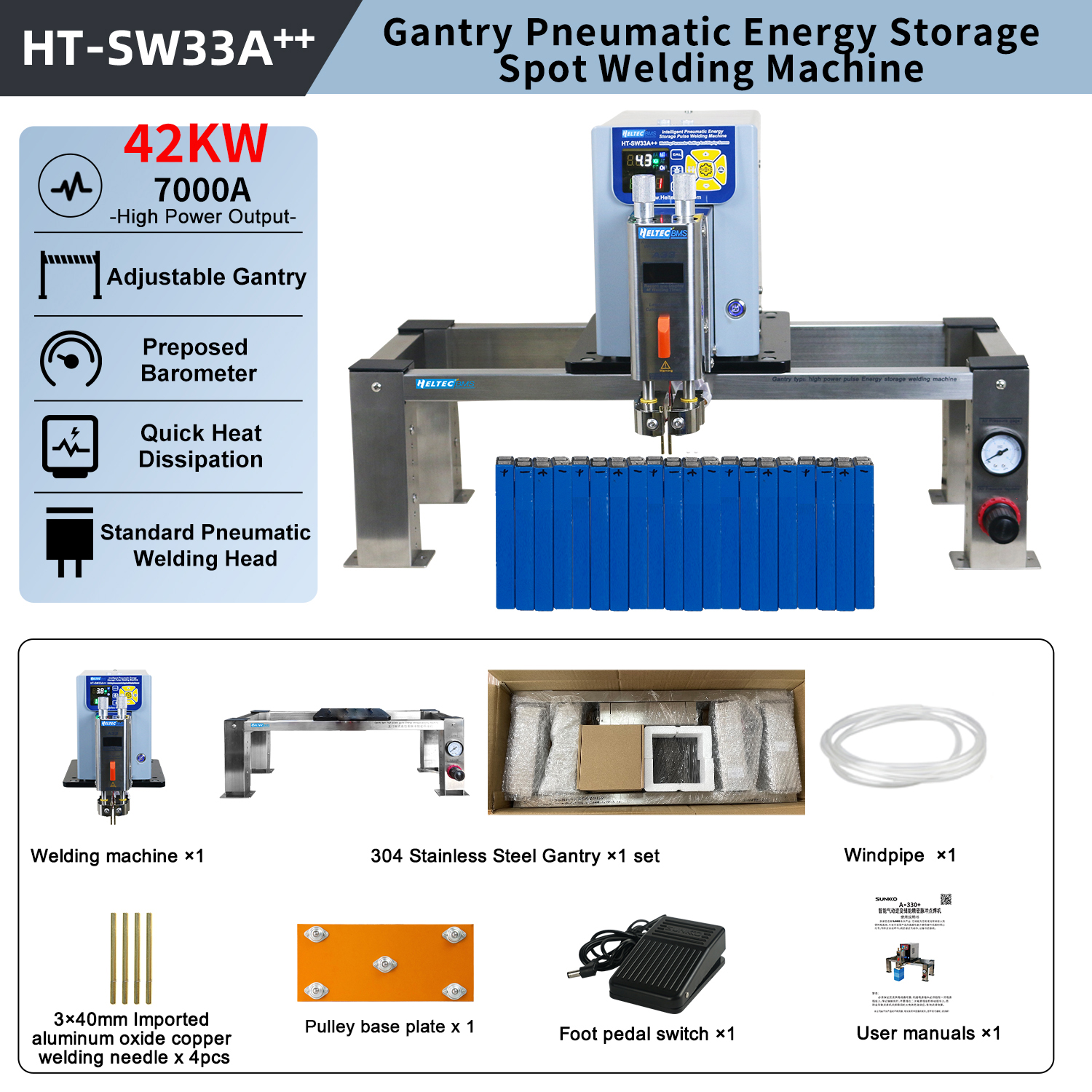

Heltec HT-SW33 series intelligent pneumatic energy storage welding machine is specially designed for welding between iron nickel materials and stainless steel materials, suitable for but not limited to the welding of ternary batteries with iron nickel and pure nickel materials. The pneumatic spot welding head uses cushioning technology to provide seamless pressure adjustment for the welding needle, as well as adjustable reset and pressing speed. The addition of laser red dot alignment ensures fast, precise positioning, minimizing errors and increasing overall work efficiency.

To improve visibility when operating at dark, LED welding needle lighting provides ample visual aid. Real-time monitoring of voltage and current through digital LED display makes it easy to evaluate welding quality. The gantry frame is made of durable 304 stainless steel to ensure stability and longevity.

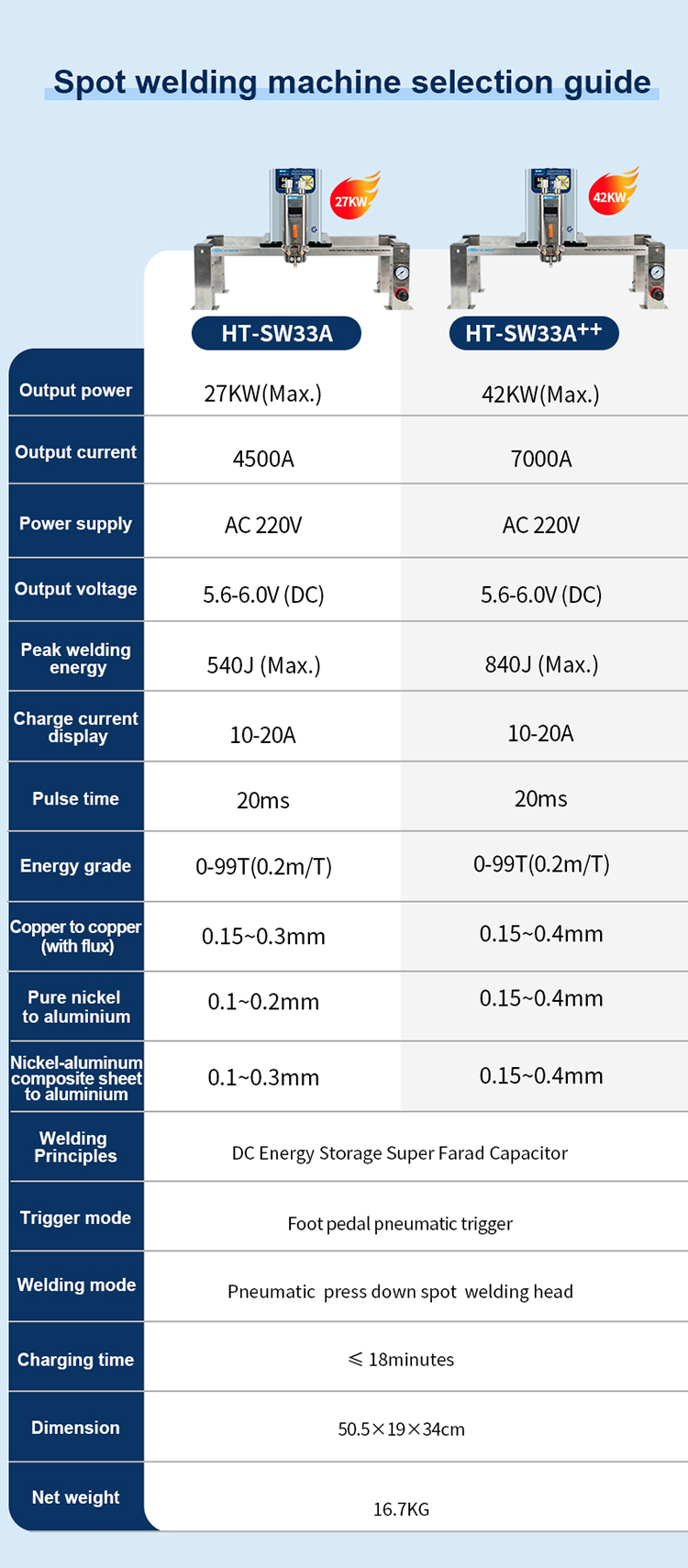

Spot Welding Machine Comparison:

| Model | HT-SW33A | HT-SW33A++ |

| Pluse power | 27KW | 42KW |

| Output maximum current | 7000A | 7000A |

| Power frequency | 50Hz | 60Hz |

| Welding voltage | DC 6V(Max.) | DC 6V(Max.) |

| Power supply | AC 110V/220V | AC110V/ 220V |

| Max input power | 150W | 150W |

| Electrode pressure | 6KG | 6KG |

| Max welding thickness | 0.5mm (Pure nickel) | 0.5mm (Pure nickel) |

| Max pneumatic stroke of electrode | 20mm | 20mm |

| Adjustable height range of gantry | 15.5-19.5cm | 15.5-19.5cm |

| Times of consecutive spot welding | 1-9times/ N(Unlimited times) | 1-9times/ N(Unlimited times) |

| Gantry weight | 10KG | 10KG |

| Gantry frame size | 60x26x18.5cm | 60x26x18.5cm |

| Dimensions | 50x19x34cm | 50x19x34cm |

| Weight | 9.26KG | 9.26KG |

Features:

- The pneumatic spot welding head is designed with buffering technology. It is convenient to adjust the pressure of the two welding needles and the speed of resetting and pressing downward the pneumatic welding heads separately.

- The HT-SW33 battery welder with laser red dot alignment function can quickly and accurately locate, reducing error rates and improving work efficiency.

- The spot welding machine with LED welding needle lighting device can effectively offer ample visual assistance during nighttime operations.

- The battery welder digital LED display screen can provide real-time monitoring of voltage and current during spot welding, thus assisting in assessing the welding quality.

- The battery welder is the first time to propose and implement a welding calibration function with zero current output to simulate the welding process and minimize the cost of errors in production.

- Semi-automated technology is a type of original creation that can be applied in continuous spot welding processes, with the number of times ranging from 1 to 9 or N times.

- The design of the front barometer and air pressure adjustment knob is conducive to monitoring and efficient adjustment.

- This HT-SW33 series battery welder is controlled by a Microcomputer. Thanks to its intelligent cooling system, it is capable of adapting to long-term batch operations.

- Adjustable output welding energy level (00-99), suitable for adjusting the welding range of various material thicknesses.

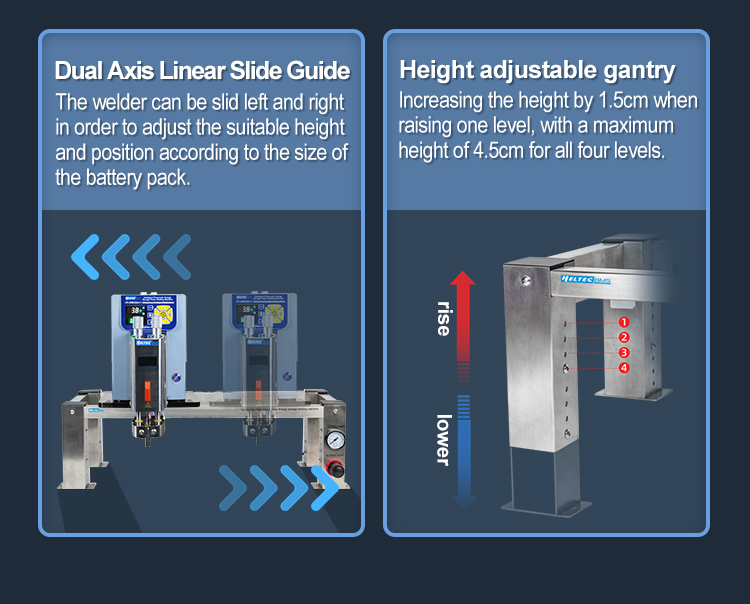

- The battery welder can be moved left or right, and its height can be adjusted to suit welding different types of lithium battery packs.

- The gantry frame is made of 304 stainless steel. It is hard, steady, and durable. The packaging is small in size and light in weight, making it easy to transport and reducing transportation costs.

Applicable Industries:

1. HT-SW33 series battery welder are for manufacturers and repair shops of battery packs for electric vehicles such as sightseeing vehicles, patrol vehicles, and sanitation vehicles;

2. Commercial energy storage power battery pack manufacturer.

Application:

1. Assembling and welding LiFePO4, battery pack, ternary lithium battery pack, etc.

2. Welding materials such as copper, aluminum, nickel aluminum composite, pure nickel, nickel plating, stainless steel, iron, molybdenum, titanium, etc.

3. The battery welder is for batch production in factories.

4. Repairing and welding the battery pack of the new energy vehicles.

Conclusion

This innovative spot welding machine is equipped with advanced features that increase efficiency, accuracy and user convenience. Experience a new level of spot welding accuracy and efficiency with Heltec pneumatic spot welder designed to meet the demands of modern industrial applications.

If you have any questions or would like to learn more, please don't hesitate to reach out to us.

Request for Quotation:

Jacqueline: jacqueline@heltec-bms.com / +86 185 8375 6538

Sucre: sucre@heltec-bms.com / +86 136 8844 2313

Nancy: nancy@heltec-bms.com / +86 184 8223 7713

Post time: Aug-13-2024