Introduction:

Welcome to the official Heltec Energy industry blog! We have introduced the working principle and application of battery spot welding machine in the previous article, now we will continue to introduce the features and application of capacitor energy storage welding machines in detail, to help you get more clues about battery spot welder and choose the most suitable one for you!

Basic Principle:

Capacitive energy storage spot welding uses capacitors to store energy. When the energy melts a small area of solder joint, the capacitor will discharge instantaneously. Compared with other welding methods such as AC machines, using it from the power grid has lower instantaneous power, balanced load in all phases, high power factor, and can provide concentrated energy to the welding area. It can obtain welded parts with good surface quality and small deformation, and can weld some difficult to weld non-ferrous metals with good thermal conductivity.

The capacitor spot welding machine consists of mechanical and electrical components, and circuit control is the core part of resistance welding technology. The energy-gathering pulse formation technology controlled by the microcomputer chip technology in the welding field is very extensive and has become the mainstream of the development of welding machine control systems.

Main Application:

1. Repair and rapid welding of lithium iron phosphate battery packs or ternary lithium battery packs used in electric vehicles, unmanned aircraft , power tools, electric appliances, robots and other equipment.

2. Rapid welding of copper/aluminum poles for various power large single cells.

3. Welding of battery connection sheets (nickel-plated / pure nickel / pure copper / nickel-plated copper sheet ), hardware parts, wires, etc.

4. Welding materials such as copper, aluminum, nickel aluminum composite, pure nickel, nickel plating, stainless steel, iron, molybdenum, titanium, etc.

Features:

-

Fast speed:

Generally, welding can be completed in just a few hundred milliseconds. For piecework with high production efficiency, capacitance welding is more suitable;

-

High temperature:

capacitor welding is used because the heating method of capacitor welding is induction heating, so the surface of the piecework can reach a high temperature in a short period of time;

-

Reliable welding:

The quality of the solder joints at the capacitor welding joint is reliable, and the stability of the solder joints will not be affected by external factors.

Our Product:

Capacitor Energy Storage Welding Machines

Our products use Super Farad Capacitors as welding power sources, low loss combiner output technology, and advanced laser welding technology, which can achieve a series of advantages such as low energy consumption, no power interference tripping, high-energy pulse output, high reliability welding, and excellent welding process. It provides an excellent and reliable foundation for equipment selection for mobile phone battery maintenance, laptop battery maintenance, and power bank production and assembly.

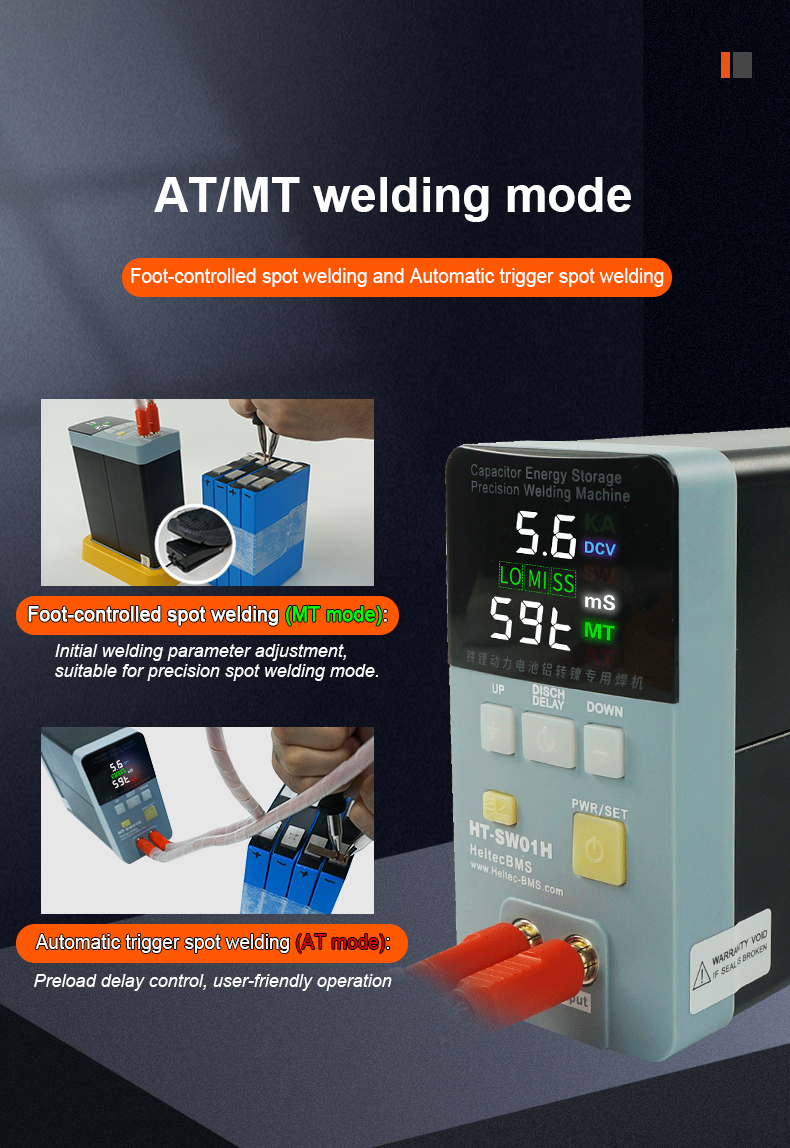

Heltec SW01 and SW02 series spot welding machines are capacitor storage welding machines. They’re high power spot welders with max peak pulse power of 42KW. You can select the peak current from 2000A to 7000A. It is easy for you to use the correct spot welding mode with the dual-mode function key on them. You can measure the connection on-resistance separately by precision micro-ohm resistance testing instrument. They can reduce labor intensity and improve efficiency with AT intelligent induction automatic trigger discharge. With LED color screen on them, it’s easy for you to view the parameters.

Product |

Power |

Standard Welding Tools |

Material and thickness(MAX) |

Applicable Battery Type |

| HT-SW01A | 10.6KW | 1.70A(16mm²) split welding pen;2. Metal butt welding seat. | Pure nickel: 0.15mmNickelage: 0.2mm |

Mobile phone battery, Polymer battery, 18650 battery |

| HT-SW01A+ | 11.6KW | 1.70B(16mm²) integrated welding pen;2.73SA press down spot welding head. | Pure nickel: 0.15mmNickelage: 0.25mm |

18650, 21700, 26650, 32650 battery |

| HT-SW01B | 11.6KW | 1.70B(16mm²) integrated welding pen;2.73SA press down spot welding head. | Pure nickel: 0.2mmNickelage: 0.3mm |

18650, 21700, 26650, 32650 battery |

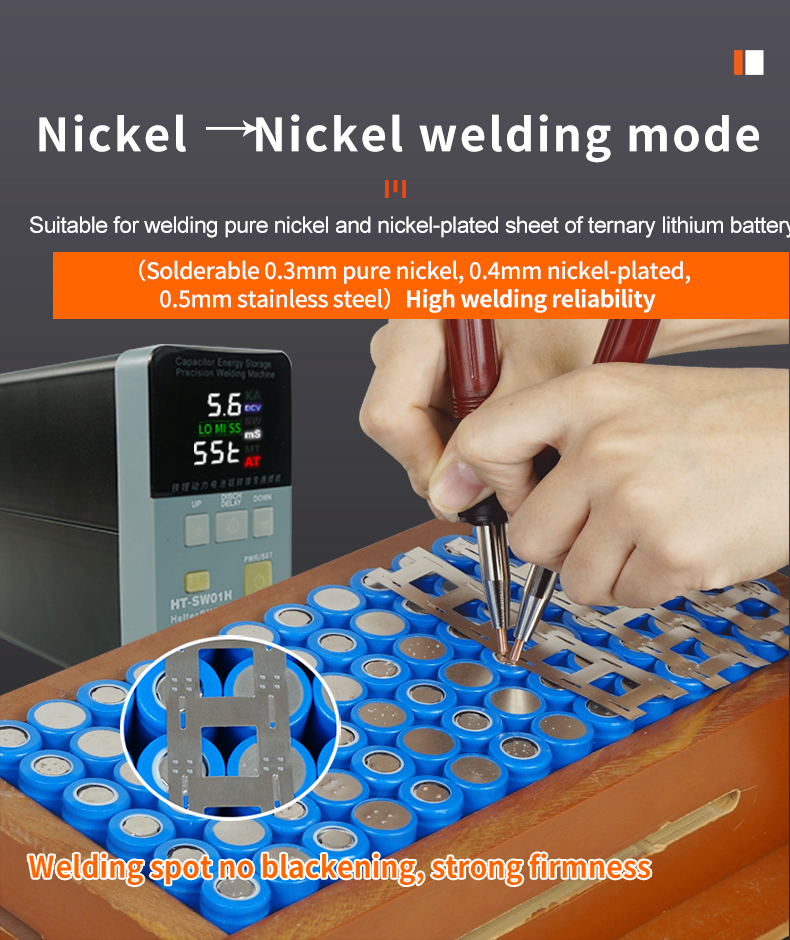

| HT-SW01D | 14.5KW | 1.73B(16mm²) integrated welding pen;2.73SA press down spot welding head. | Pure nickel: 0.3mmNickelage: 0.4mm |

18650, 21700, 26650, 32650 battery, LFP aluminum / copper electrode |

| HT-SW01H | 21KW | 1.75 (25mm²) split welding pen;2.73SA press down spot welding head. | Aluminum nickel composite slice: 0.15mmPure nickel: 0.3mmNickelage: 0.4mm |

18650, 21700, 26650, 32650 battery, LFP aluminum/copper electrode |

| HT-SW02A | 36KW | 75A(35mm²) split welding pen | Copper with flux: 0.3mmAluminum nickel composite slice: 0.2mmPure nickel: 0.5mm

Nickelage: 0.6mm |

Copper sheet, 18650, 21700, 26650, 32650 battery, LFP aluminum / copper electrode |

| HT-SW02H | 42KW | 1. 75A(50mm²) split welding pen2. Milliohm resistance measuring pen | Copper with flux: 0.4mmAluminum nickel composite slice: 0.4mmPure nickel: 0.5mm

Nickelage: 0.6mm |

Copper sheet, 18650, 21700, 26650, 32650 battery, LFP aluminum / copper electrode

|

| HT-SW33A | 27KW | A30 pneumatic spot welding device | Copper with flux: 0.3mmAluminum nickel composite slice: 0.3mmPure nickel: 0.35mm

Nickelage: 0.45mm |

Copper sheet, 18650, 21700, 26650, 32650 battery, LFP aluminum / copper electrode |

| HT-SW33A++ | 42KW | A30 pneumatic spot welding device | Copper with flux: 0.4mmAluminum nickel composite slice: 0.5mmPure nickel: 0.5mm

Nickelage: 0.6mm |

Copper sheet, 18650, 21700, 26650, 32650 battery, LFP aluminum / copper electrode |

Videos:

HT-SW01H:

HT-SW02H:

Conclusion:

The above is an introduction to the working principle, application, and characteristics of capacitor energy storage welding machines. In the next blog post, we will continue to introduce the characteristics and applications of pneumatic spot welding machines, please look forward to it!

If you have any questions or would like to learn more, please don't hesitate to reach out to us.

Post time: Dec-20-2023