Introduction:

5-minute charging with a range of 400 kilometers! On March 17th, BYD released its "megawatt flash charging" system, which will enable electric vehicles to charge as quickly as refueling.

However, in order to achieve the goal of "oil and electricity at the same speed", BYD seems to have reached the limit of its own lithium iron phosphate battery. Despite the fact that the energy density of lithium iron phosphate material itself is approaching its theoretical limit, BYD is still pushing product design and technological optimization to the extreme.

Play to the extreme! 10C lithium iron phosphate

Firstly, according to the information released at BYD's press conference, BYD's flash charging technology uses a product called "flash charging blade battery", which is still a type of lithium iron phosphate battery.

This not only breaks the dominance of high rate lithium batteries such as high nickel ternary batteries in the fast charging market, but also allows BYD to push the performance of lithium iron phosphate to the extreme again, allowing BYD to continue its market value in the technology route of lithium iron phosphate batteries.

According to the data released by BYD, BYD has achieved a peak charging power of 1 megawatt (1000 kW) for some models such as the Han L and Tang L, and a flash charge of 5 minutes can supplement 400 kilometers of range. Its' flash charging 'battery has reached a charging rate of 10C.

What concept is this? In terms of scientific principles, it is currently recognized in the industry that the energy density of lithium iron phosphate batteries is close to the theoretical limit. Usually, in order to ensure higher energy density, manufacturers will sacrifice some of their charge and discharge performance. Generally, 3-5C discharge is considered the ideal discharge rate for lithium iron phosphate batteries.

However, this time BYD has increased the discharge rate of lithium iron phosphate to 10C, which not only means that the current has nearly doubled, but also means that the internal resistance and thermal management difficulty have doubled.

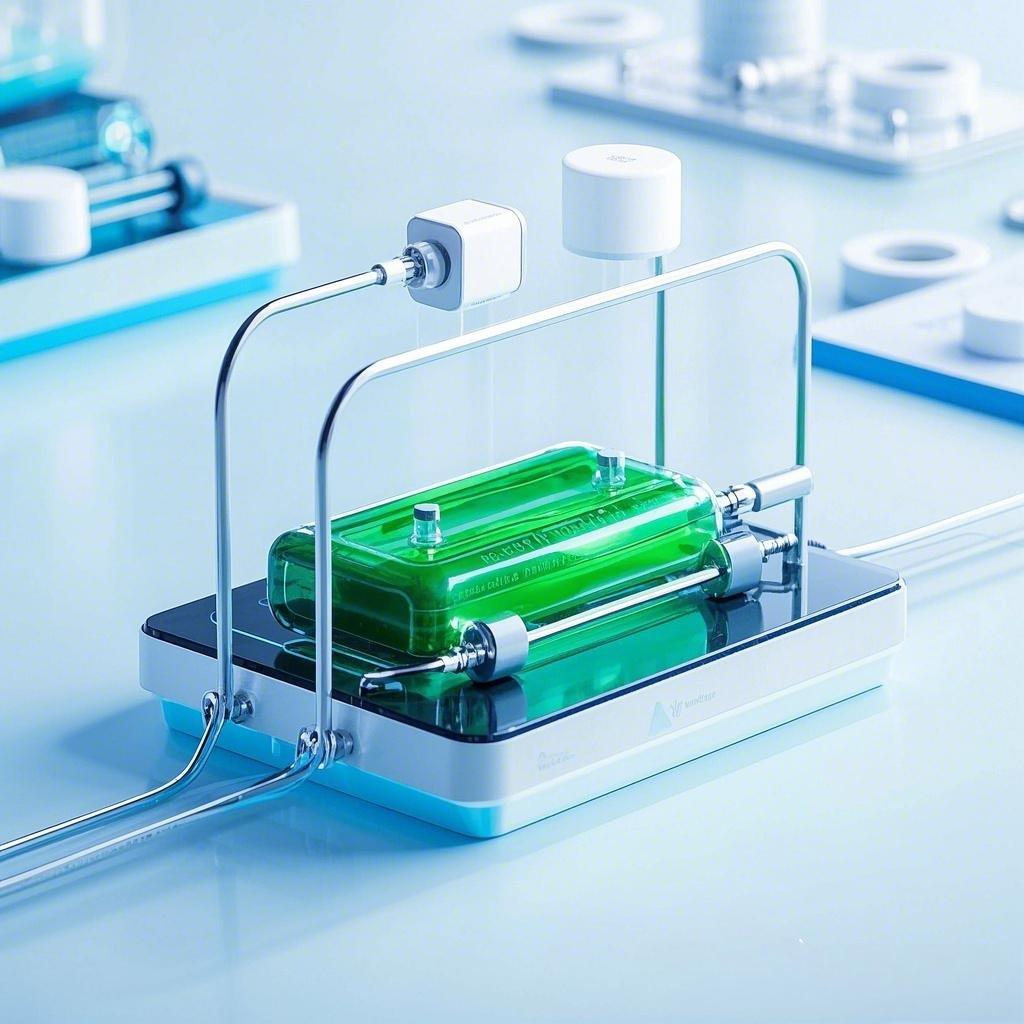

BYD claims that on the basis of the blade, BYD's "flash charging battery" optimizes the electrode structure of the blade battery, reducing the migration resistance of lithium ions by 50%, thus achieving a charging rate of over 10C for the first time.

On the positive electrode material, BYD uses high-purity, high-pressure, and high-density fourth generation lithium iron phosphate materials, as well as nanoscale crushing processes, special formula additives, and high-temperature calcination processes. A more perfect internal crystal structure and shorter diffusion path for lithium ions increase the migration rate of lithium ions, thereby reducing battery internal resistance and improving discharge rate performance.

In addition, in terms of the selection of negative electrodes and electrolytes, it is also necessary to choose the best from the best. The application of artificial graphite with higher specific surface area and the addition of high-performance PEO (polyethylene oxide) electrolytes have also become necessary conditions to support 10C lithium iron phosphate batteries.

In short, in order to achieve performance breakthroughs, BYD spares no expense. At the press conference, the price of the BYD Han L EV equipped with a "flash charging" battery has reached 270000-350000 yuan, which is nearly 70000 yuan higher than the price of its 2025 EV intelligent driving version (701KM Honor model).

What is the lifespan and safety of flash charging batteries?

Of course, for high-tech, being expensive is not a problem. Everyone is still concerned about the quality and safety of the product.Regarding this, Lian Yubo, Executive Vice President of BYD Group, stated that flash charging batteries can maintain a long lifespan even when charged at ultra-high rates, with a 35% increase in battery cycle life.

It can be said that BYD's answer this time is quite fair and full of skills, at least not denying the impact of overcharging on battery life.

Because in principle, rapid charging and discharging will have irreversible effects on the battery structure. The faster the charging and discharging speed, the greater the impact on the battery cycle life. As for supercharging, long-term use often reduces battery life by 20% to 30%. Therefore, most manufacturers recommend overcharging as an emergency charging option.

Some manufacturers will introduce overcharging on the basis of improving the cycle life of the battery itself. The reduction in battery life caused by overcharging is offset by the increase in battery life by the manufacturer, ultimately allowing the entire product to maintain good charging and discharging performance within its expected lifespan.

In addition, in order to achieve "flash charging", BYD has also implemented a series of system upgrades around the shortcomings of lithium iron phosphate batteries and the entire power supply system.

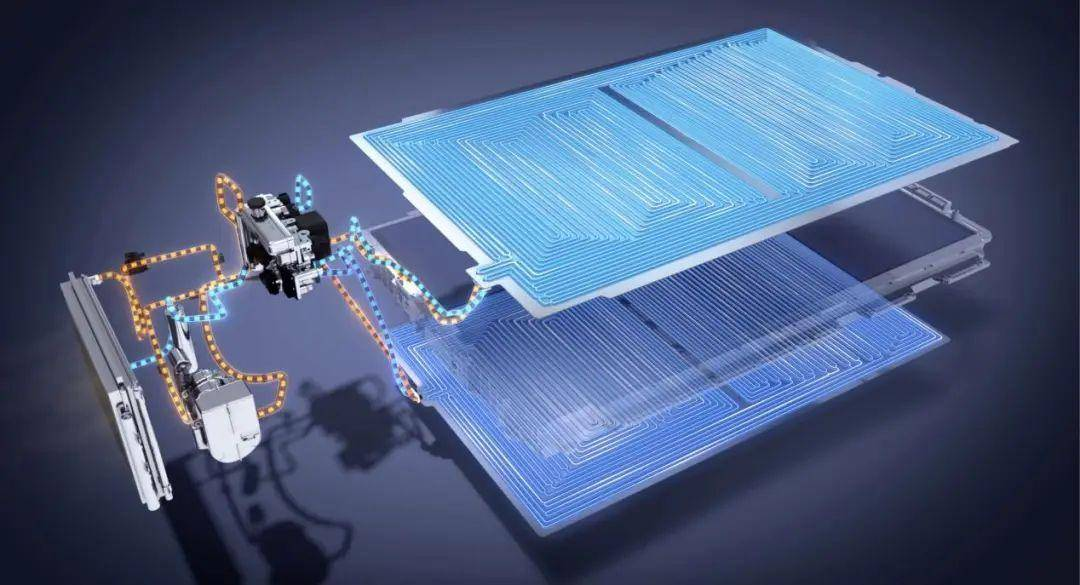

In order to compensate for the shortcomings of low temperature performance in lithium iron phosphate batteries, BYD's "flash charging" system introduces a pulse heating device to maintain the rapid charging and discharging performance of the battery through self heating in cold environments. At the same time, in order to cope with the battery heating caused by high-power charging and discharging, the battery compartment is integrated with a composite liquid cooling temperature control system, which directly takes away the battery heat through the refrigerant.

In terms of safety performance, lithium iron phosphate has once again proven its value. According to BYD, its "flash charging" blade battery easily passed the 1200 ton crushing test and 70km/h collision test. The stable chemical structure and flame retardant properties of lithium iron phosphate once again provide the most fundamental guarantee for the safety of electric vehicles.

Facing a charging bottleneck

Perhaps most people have no concept of megawatt level power, but it is important to understand that 1 megawatt may be the power of a medium-sized factory, the installed capacity of a small solar power plant, or the electricity consumption of a community of one thousand people.

Yes, you heard it right. The charging power of a car is equivalent to that of a factory or a residential area. A supercharging station is equivalent to the electricity consumption of half a street. This scale of electricity consumption will be a huge challenge for the current urban power grid.

It's not that there's no money to build charging stations, but to build super charging stations, it's necessary to renovate the entire city and street's power grid. Just like making dumplings specifically for a plate of vinegar, this project requires a lot of effort. With its current strength, BYD has only planned the construction of over 4000 "megawatt flash charging stations" nationwide in the future.

4000 'megawatt flash charging stations' are actually not enough. Flash charging "batteries and" flash charging "cars are just the first step towards achieving" oil and electricity at the same speed ".

With the breakthroughs in electric vehicle and battery technology, the real problem has actually begun to shift to the construction of power facilities and energy networks. Both BYD and CATL, as well as other battery and electric vehicle companies in China, may face greater market opportunities in this regard.

Request for Quotation:

Jacqueline: jacqueline@heltec-bms.com / +86 185 8375 6538

Sucre: sucre@heltec-bms.com / +86 136 8844 2313

Nancy: nancy@heltec-bms.com / +86 184 8223 7713

Post time: Mar-20-2025