Capacitor Welding Machine

HT-SW02A Hand Held Welding Machine 36KW High Power Mini Spot Welder

Specifications

- 36KW 6000A (HT-SW02A Spot Welder)

Product Information

| Brand Name: | HeltecBMS |

| Origin: | Mainland China |

| Certification: | CE/WEEE |

| Warranty: | 1 year |

| MOQ: | 1 pc |

| Useage: | spot welding |

Features

1. The HT-SW02A spot welder with high-frequency inverter super energy storage capacitor discharge technology eliminates interference to AC power supply, and avoid switch tripping situation.

2. The China's patented energy storage control and low-loss metal bus technology maximizes the burst energy output.

3. The energy-concentrated pulse formation technology controlled by the microcomputer chip operation ensures the formation of reliable solder joints in milliseconds.

4. HT-SW02A spot welder has intelligent program combined with multi-function parameter display screen, the management of welding is clear at a glance, with high proficiency.

5. The HT-SW02A spot welder with up to 36KW output power, which can meet the needs of power battery welding.

6. The HT-SW02A spot welder with an intelligent display control panel, the output level can be flexibly adjusted according to the thickness of different weldments.

7. The machine up to 6000A pulse welding current can weld 0.3mm pure copper sheet to the copper electrode (with flux).

8. Dual-mode spot welding to achieve precise,fast and efficient welding, which is convenient for welding different weldments.

9. The first dual welding tool mode combination is convenient for users weld a wide range of work pieces flexibly, such as batteries and metal parts.

10. The unique real-time display of welding pulse current can monitor each welding current and avoid false welding of solder joints.

11. The HT-SW02A spot welder supports optional removable professional welding pens with different functions and performances to realize welding work from ultra-thin to ultra-thick weldments.

12. The HT-SW02A spot welder with ultra-low loss, high-efficiency performance design, professional industrial-grade manufacturing process, to ensure the machine for a longtime use without getting hot.

Applications

Widely used for welding of large single battery pack and other materials:

1. The HT-SW02A spot welder can repair and rapid welding of lithium iron phosphate battery packs or ternary lithium battery packs used in electric vehicles , unmanned aircraft, power tools, electric appliances, robots and other equipment.

2. The spot welder can rapid welding of copper/aluminum poles for various power large single cells.

3. Welding of battery connection sheets (nickel-plated/pure nickel/pure copper/ nickel-plated copper sheet), hardware parts, wires, etc.

4. The HT-SW02A spot welder can rapid welding of stainless steel, iron sheet, brass, titanium, molybdenum and other materials.

Customization

- Customized logo

- Customized packaging

- Graphic customization

Package

1. Battery repairer *1set.

2. Anti-static bag, anti-static sponge and corrugated case.

Purchase Details

- Shipping From:

1. Company/Factory in China

2. Warehouses in United States/Poland/Russia/Brazil

Contact Us to negotiate shipping details - Payment: 100% TT is recommended

- Returns & Refunds: Eligible for returns and refunds

Video

Parameters

| Model | HT-SW02A | Charging Current | 10-20A |

| Power Supply | AC 110V and 220V optional | Peak Welding Energy | 720J |

| Pulse Power | 36KW(Peak) | Welding Mode | MT:Foot control mode AT:Automatic welding mode |

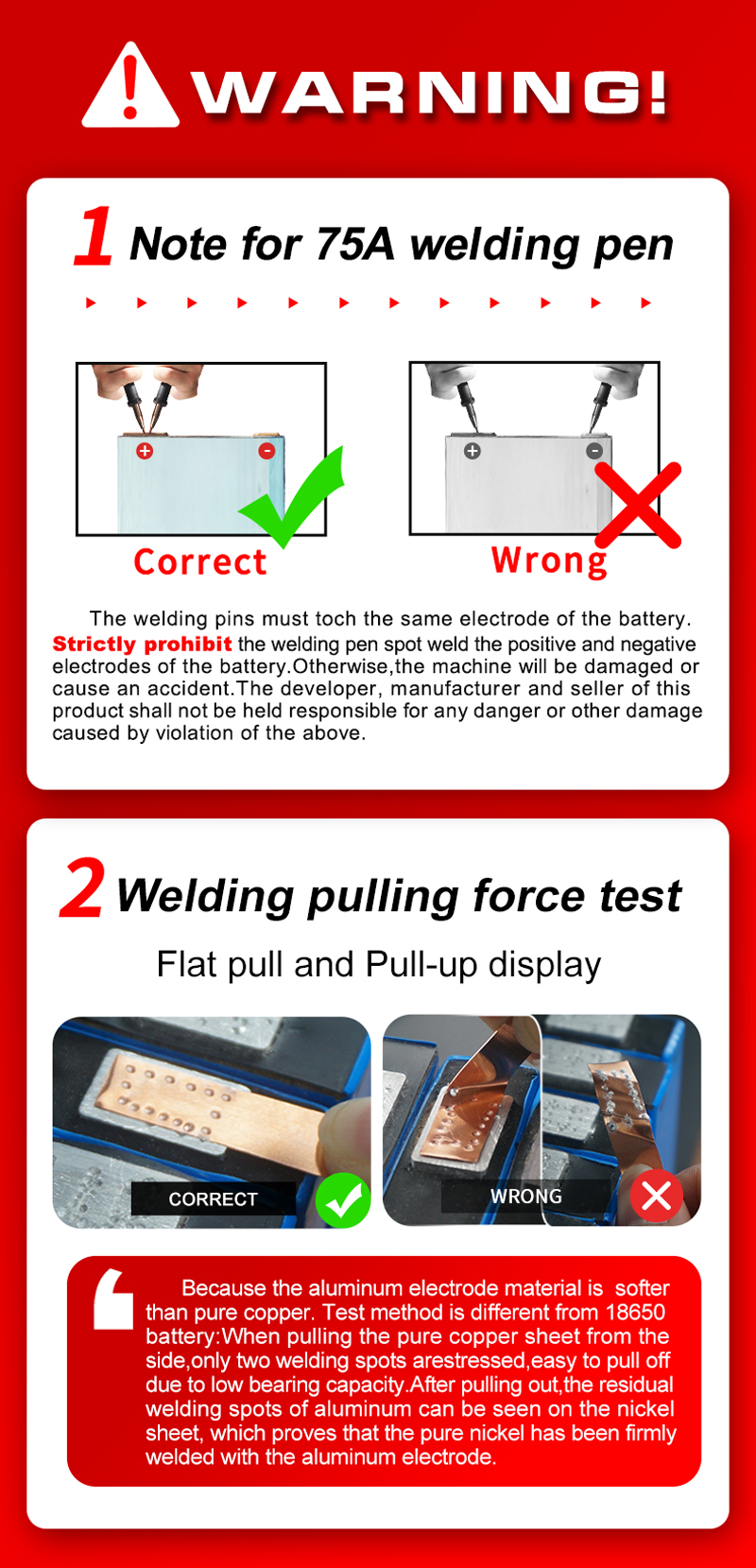

| Energy Grade | 0-99T(0.2ms/T) | Welding Tool | 75A Split spot welding pen |

| Pulse Time | 0~20ms | AT Preloading Delay | 300ms |

| Output Current | 6000A(Peak) | Charging Time | About 18 min |

| Output Voltage | 5.6-6.0V | Welding Thickness | 0.1~0.3mm Copper (with flux) 0.1-0.5mm Pure nickel |

| Dimension | 24(L)x14(W)x21(H)cm | Net Weight | 6.5 KG |

* We keep upgrading products to meet requirements of our clients, please contact our sales person for more accurate details.

Welding tool

S-75Asplit spot welding pen

|

Model |

S-75A (35mm2) |

Total length |

About 610mm |

|

Cable cross-section |

35mm2 |

Welding pin diameter |

02mmX15mm |

|

The max carry current |

3500A-6000A |

Internal Resistance |

<0.35mQ |

Product Instruction:

Request for Quotation:

Jacqueline: jacqueline@heltec-bms.com / +86 185 8375 6538

Sucre: sucre@heltec-bms.com / +86 136 8844 2313

Nancy: nancy@heltec-bms.com / +86 184 8223 7713